Quality Management Software Moves Toward Quality 4.0

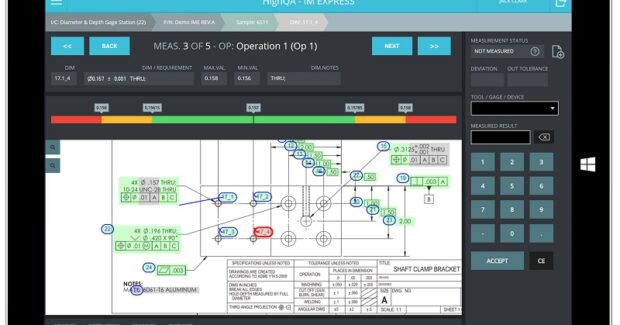

Inspection Manager from High QA automatically extracts GD&T requirements from 2D drawings and 3D models, digitizes prints with automatic ballooning, creates inspection plan reports and stores all the information and measurement tools in a centralized database.

Posted: October 31, 2019

Inspection Manager™ quality management software from High QA, Inc. (Hazlet, NJ) uses its one-click architecture to automatically extract GD&T requirements from 2D drawings and 3D models, digitizes prints with automatic ballooning, creates inspection plan reports, stores all the information and measurement tools in a centralized database, and much more. “Inspection Manager makes the move towards Quality 4.0 – an integral aspect of Industry 4.0 – practical for many manufacturers,” said Sam Golan, the chief executive officer and founder of High QA. “The time-savings alone is astounding because a large percentage of shops are still marking up their 2D parts prints with paper and pencils to extract the quality parameters of the job. The centralized database is also extremely helpful for users so they can aggregate useful inspection information data to make better process decisions from one integrated and complete source. This is quite a comprehensive package of quality management functions: automated, usable, and accessible.”

New features in Inspection Manager surround manufacturing operations, bulk updating, assemblies, job lifecycles, materials management and handling non-conformance issues and processes. “One of the most exciting additions is the ability to now support ballooning of welding dimensions directly inside Inspection Manager using our intuitive ballooning interface,” noted Golan. Other helpful benefits include the ability to work in Dual Units – metric or English – and convert those with just one click. The chosen unit is the one that propagates through to the ballooned PDF and the final reports generated, such as AS9102 FAI Forms 1 and 2. Users can store unlimited design revisions with the original and converted units.

An integrated SPC module within Inspection Manager allows users to monitor variations in real-time in the manufacturing process during the inspection process. The inspection results can be captured automatically from a wide range of metrology tools. Manual data can be collected on the shop-floor and added in real-time using a tablet-based application for Inspection Manager, IM Explorer™ and IM eXpress™. All of the metrology tools, systems, and certificates can also be stored and managed in Inspection Manager’s centralized database and can alert the customer when calibrations are due and when certs need to be updated.

High QA, Inc., 1 Bethany Road, Suite 26, Hazlet, NJ 07730, 888-727-1266, [email protected], www.highqa.com.