Laser-Enhanced Calibration Improves Programmed Path Performance

ColeTech used a Radian 6DoF tracker from API to correct errors in joint angles and link lengths for deflashing molded parts.

Posted: October 13, 2019

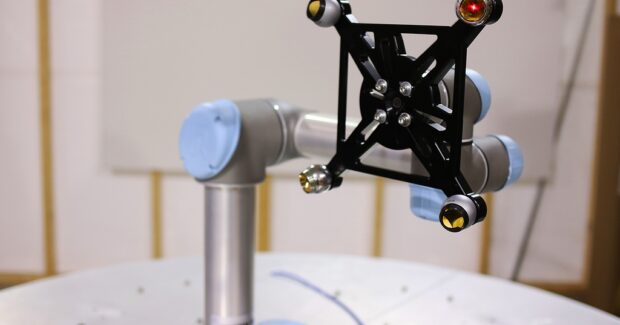

Since 2003, ColeTech Manufacturing (Columbus, IN) has helped customers ranging from small manufacturers to Fortune 500 companies automate pick-and-place, deburring, and plastic parts trimming applications. When the company needed to improve deflashing of molded parts, engineering director Steve Richard contracted a metrology systems provider to recalibrate a Universal Robots (Ann Arbor, MI) arm: API Services, a division of API Metrology Equipment Ltd. (Rockville, MD), used their Radian 6DoF (six degrees of freedom) laser tracker with robot measuring software (RMS) to improve programmed motion path accuracy. A multiple spherically-mounted retroflector (SMR) tracker target frame was mounted onto the robot end-effector that measures position and orientation. The software then exercised all robot joints, using ISO 9283 guidelines to check accuracy, repeatability, pose, distance, drift, and overshoot.

Measuring a free point cloud consisting of 80 points, the software generated a new Denavit-Hartenberg (DH) frame model parameter set that ColeTech used to correct errors in joint angles and link lengths. The revised parameter can be input into the robot controller or, as they did in this project, used to update the robot motion path program. The robot working envelope can be defined applicable to the planned robot application.

“The additional accuracy allows us to provide a better outcome for the customer regardless of application,” said Richard. “API was able to directly interface with our RoboDK programming software for robot calibration, making loading the new parameters seamless.”

ColeTech Manufacturing, 4050 North Long Road, Columbus, IN 47203, 812-378-0800, Fax: 812.418.0600, [email protected], www.coleusa.com.

API Metrology Equipment Ltd., 15000 Johns Hopkins Drive, Rockville, MD 20850, 800-537-2720, Fax: 301-990-8648, www.apimetrology.com.