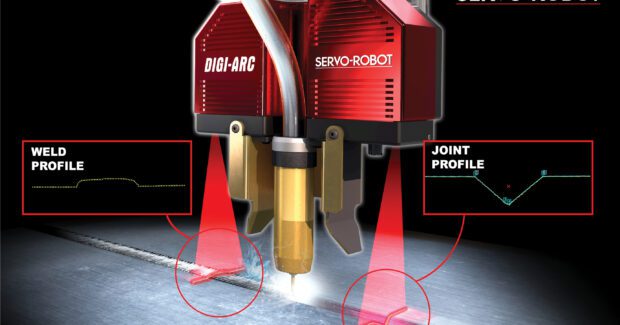

Intelligent Vision Systems Improve Weld Inspection

The DIGI-ARC real-time seam tracking system and WiKi-SCAN+ portable weld inspection system from Servo-Robot monitor, analyze, and improve weld processes.

Posted: October 22, 2019

For concurrent, real-time seam tracking and weld inspection for most arc welding processes, the DIGI-ARC system from Servo-Robot Inc. (St-Bruno, QC) provides real-time process control and the ability to inspect almost any weld. It can be used in conjunction with both hard automation and standard industrial robots in applications ranging from automotive to heavy fabrication. This combination of real-time feedback allows for greater adaptive control of the welding process. Also, the next-generation WiKi-SCAN+ portable weld inspection system from Servo-Robot is more compact for better access to tight joints and improved ergonomics. Its increased measurement accuracy and redesigned user-interface gives shops a greater ability to monitor, analyze, and improve their weld processes.

Servo-Robot Inc.,1370 Hocquart, St-Bruno, Quebec, Canada, J3V 6E1, 450-653-7868, Fax: 450-653-7869, www.servorobot.com.