Unfolding the Future of Sheet Metal

Shops spend lots of money on cutting tools to become more efficient. But for the price of a cup of coffee each month, the cloud-based platform from Paperless Parts identifies manufacturability issues, avoiding costly mistakes and saving the entire business time and money.

Posted: September 5, 2019

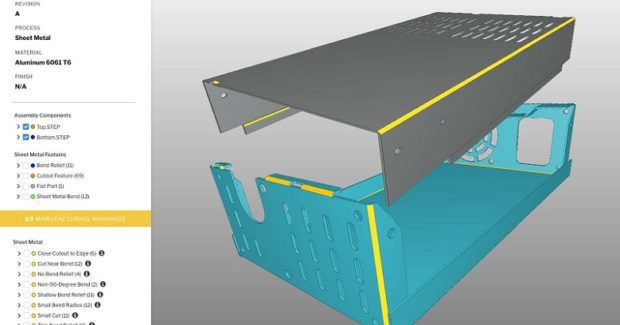

In Booth A-3642, Paperless Parts Inc., (Boston, MA) features Paperless Parts, a secure, ITAR-registered and compliant cloud-based platform for sheet metal software support that enables fabricators to view 2D and 3D data, detect manufacturability issues and rapidly quote simple to complex sheet metal parts and assemblies.

Its geometry engine analyzes sheet metal components to identify features such as bends, holes, thickness irregularities and other relevant information for the sheet metal process. Assemblies are recognized and can be quoted as one line item, built up from all underlying components and purchased items such as hardware, rather than the traditional method of quoting each part separately. The software unfolds the sheet metal part, providing the unfolded dimensions and thickness needed for material ordering.

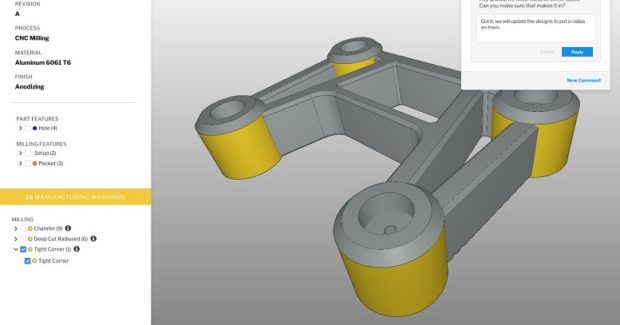

Like milling, turning, and other supported manufacturing processes, Paperless Parts identifies manufacturability issues to save your shop time and money, avoiding costly mistakes.

A January 2021 enhancement to the quoting platform is Paperless Search, which empowers estimators to prepare more accurate and consistent quotes by easily finding and referencing data from historical quotes and past jobs.

According to a recent Paperless Parts survey of more than 400 U.S. manufacturing part buyers and engineers within procurement, 67% of respondents expect a quote in less than 24 hours and only 6% of respondents are willing to wait longer than three days. This data shows that manufacturers must return RFQs as quickly as possible or risk their chances of winning the job. However, many job shops and contract manufacturers still use manual tools and outdated processes that make it hard to engineer quotes and often overlook existing materials within the organization that could be helpful in speeding up response time and providing consistent and accurate quotes.

Paperless Search addresses these challenges by breaking data out of locked filing cabinets and helping make sense of it by putting it into a single, searchable and secure database. Manufacturers can now easily find all data and files loaded into the Paperless Parts platform, including historical quoting and parts information, in a digital format. This ability to search anything not only improves customer service by enabling a prompt response to RFQs, but also empowers the shop’s front office to field inquiries efficiently because they can reference previous parts, quotes and orders quickly.

“As consumers, we often take for granted the ability to easily find the information we need in seconds by entering a few hasty keywords,” said Jason Ray, co-founder and CEO at Paperless Parts. “For resource-strapped manufacturing shops, that is a luxury they have longed for when going through the tedious process of estimating jobs. Paperless Search is a powerful tool that will only become more valuable as data capture and analytics become more prevalent in modern machine shops and we are eager to see how much more nimble our customers can be armed with the information uncovered in their searches.”

Additional features of Paperless Search:

- Unlimited Data Capture – This feature makes every word in a user’s account searchable, including information such as comments in collaborative chat tools; part names and quality certifications on prints from past jobs; and file names. Users can search for exact words or portions of words.

- Data Transformation – Paperless Parts turns raw data into meaningful insight, such as connecting critical tolerances from technical drawings to quote items; supporting file names to jobs won; and chat conversations to specific parts. Results are also ranked using a fine-tuned scoring algorithm to deliver the most relevant results. As a result, users can type plain-English terms into the search box and easily find technical information or other details buried in the data of past quotes and jobs.

- Display and Location Markers – For ease of use, all search results are displayed by highlighting exactly what terms matched. Clicking a result will take the user directly to a detailed view of the matched entity, which may be a part in the 3D viewer or a quote item. Users can also look at other fields to quickly zero in on supporting data, such as grouping quote items by their materials or customer name for identification.

Design for Manufacturability (DFM)

These design for manufacturability (DFM) settings can be customized to the fabricator’s capabilities – an industry first: Now every fabricator can instantly identify DFM issues based on their own shop’s manufacturing capabilities, enabling upfront communication with both their customers and within their team. All of the geometric analysis results can be fed into Paperless Parts Quoting, streamlining the quoting process for fabricators and leveling up the customer experience with the Digital Quote.

“This platform brings front-end sheet metal manufacturing tools into the 21st century, enabling shops to actually identify manufacturability issues at the time of quoting and then use advanced quoting tools to push out quotes quickly. Shop owners will appreciate how this geometry engine finds ‘gotchas’ so that unprofitable parts don’t get quoted incorrectly,” explained Jay Jacobs, the co-founder of Paperless Parts who was also the founder of Rapid (Nashua, NH), one of the world’s largest quick-turn sheet metal fabricators (Rapid Sheet Metal) and the world’s second largest quick-turn CNC machine shop (Rapid Machining), before selling them to ProtoLabs in 2017 for $120 million.

Also on display will be a new manufacturing communication tool aimed to facilitate collaboration as parts go from design and engineering to the final manufactured part on the shop floor.

“As manufacturers look to Industry 4.0, Industrial Internet of Things (IIoT) and Smart Manufacturing practices to modernize the shop floor, most businesses are forgetting about connecting a key piece – their people,” said Jason Ray, chief executive officer of Paperless Parts. “This platform helps manufacturers bridge the skills gap by giving everyone secure access to the communication power of 3D models and the most advanced geometric analysis engine in the world.”

Paperless Parts is scalable and simple to use for teams of one person to 10,000 people, who can view and annotate all major CAD formats and technical data. Its geometric analysis engine catches manufacturability issues customized to each manufacturing business and streamlines communication between customers, the front office and the shop floor.

Advanced features, such as geometric part search, allow manufacturing teams to leverage geometry to quickly find historical or similar files, simplifying the chaos of a team’s shared drive. “We’ve seen how communication tools like Slack and Office 365 transform small and large businesses through better communication,” added Ray. “For manufacturing, the missing piece with all of these solutions is the proper context of the part and corresponding technical data. Paperless Parts provides communication in the context of geometry.” For shops that are looking to take advantage of Industry 4.0 technologies, this platform is the easiest way to build buy-in from your team and start modernizing your shop.

“As mold designs transition from our engineering team to the shop floor, communication is fragmented,” said Scott Duncan, president of F&M Tool and Die (Leominster, MA), who leverages Paperless Parts to modernize his business and improve his team’s communication. “We used post-it notes, email, marked up red-lined prints and walked back and forth between the engineering office and the shop floor in order to communicate. Because notes and decisions are not captured in a single place, there is a lack of transparency that causes confusion and errors. When the steel alone for a mold often runs over $100K, errors can be catastrophic. A better solution that the team can easily embrace is critical for reducing risk. This platform offers a very elegant, simple system that our team is excited to use on tablets and computers, giving everyone a single point of communication.”

“Manufacturers spend tens of thousands of dollars on cutting tools every year to make their businesses more efficient,” said Jacobs. “For the price of a cup of coffee per month, you can give each member on your team access to the most powerful communication tool in manufacturing.”