The Practical Impact of Industry 4.0 – Part Three: Connecting the Dots

Building the Smart Factory starts with digital processes and automated machines, but it ends with intelligent connections between resources and tasks. Linking together people, machines and software inside a plant enhances the capabilities of each and creates a system that is more valuable than the sum of its parts.

Posted: September 3, 2019

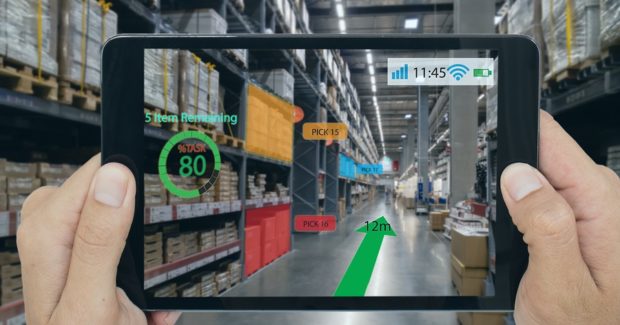

The roadmap for building the Smart Factory begins with digital processes and automated machines, but it ends with intelligent connections between resources and tasks. A computer by itself is a powerful tool, but tie a group of computers together in a network and suddenly you have a system which is more valuable than the sum of its parts. The same is true of production resources: By linking together people, machines and software within a factory, the capabilities of each are enhanced. It’s easy to think of fabricating as a series of discrete steps: cut, form, weld, finish, assemble, etc., but the reality is more complicated than that. Looking at footsteps in sand, you can see where a person’s feet have landed, but you don’t see the work that the legs did between each of those footfalls. Likewise, the journey of a product through a production line is not really a sequence of clearly defined moments, but a continuum that is always flowing from somewhere and to somewhere. And oftentimes, when we look carefully at the whole moving picture rather than just the individual steps, we realize that what is happening in between the steps is where a lot of the action is.

Value-stream mapping is an old trick that production personnel use to understand manufacturing processes and find potential improvements, and it has served many businesses well for many years. Still, the classic value stream map, as useful of a tool as it can be, in some ways represents an outmoded way of thinking because it breaks down that continuous activity that exists on the factory floor and turns it into a series of snapshots, connected by convenient lines or arrows. It doesn’t take much time on a factory floor to realize that arrows do not move product from point A to point B – people and equipment do that. The logical extension of this is: If people and equipment are needed to facilitate production flow, then those are places that can also be optimized for cost and productivity, just like the manufacturing steps that they are connecting. A lot of lean manufacturing principles are oriented around those connections, such as reducing the physical steps a person must take to accomplish their tasks or providing rolling carts that are ergonomic and well-suited to the products to be moved.

Industry 4.0 aims to take that way of thinking and advance it further: It’s great to build a nice cart to help people move material, but have we asked ourselves whether people need to be moving that material at all?

Consider a major piece of capital equipment: a material storage and retrieval system for sheets. For decades many factories decided to move from simple rack storage of sheet metal to material handling systems that take advantage of vertical space and provide the ability to have an automatic crane deposit and retrieve pallets of raw material as needed. These towers can often also be connected directly to the machine in order to eliminate the need for a person to deliver raw material for processing. While the advantages of this setup are obvious, it also comes with some limitations. If you want to have the storage tower feeding machines automatically, it has to be somewhat centrally located in the production area, which may not be close to the receiving bay where raw materials shipments arrive, therefore increasing the distance raw material must be transported for storage. Machines will need a direct physical connection to the storage, so the layout of your processing equipment becomes dictated by the layout of the storage instead of the needs of your business.

If you need to place a machine somewhere else, you are back to taking raw material manually from the storage to the equipment. And as your business evolves, you may find your decision-making with regards to future equipment investments is constrained by direct compatibility to your storage system. Enter the role of the AGV (autonomously-guided vehicle). If a pallet of raw material can be delivered anywhere inside of a facility automatically, using ordinary floor space to travel (read: no special construction effort or fixed trackways), suddenly the way we lay out our automated factory becomes much more flexible. Our material storage can now be located wherever it is convenient, and so can our machinery. The safety hazards associated with handling material are eliminated, and instead of having to lift, bend and push carts around, people can focus more on value-adding tasks. Our AGVs could also be used to move products between production steps, such as from a press brake to a welding booth, further streamlining the connections between those processes and eliminating unnecessary labor. If our business model changes and the needs of the factory change with it, we can invest in new equipment and modify the production map without having to work around the material storage.

Another technology that is helping manufacturers tie things together is the product tracking system. These take the form of small devices, usually a few inches across (imagine a hockey puck), made of a durable plastic housing and containing a transmitter. These devices are placed on products, in boxes, and on pallets or carts, continuously broadcasting their location to satellite receivers mounted around the factory floor. When set up, the receivers are calibrated to a map of the factory so that they can represent the locations of the transmitters in terms that a person can quickly understand. These systems can boast impressive accuracy, down to ± 6 in – more than precise enough to help someone quickly locate a part or assembly that is needed even in a huge factory. By integrating a bar- or dot-matrix-code on the trackers and equipping our factory team with a computer and a code scanner, a team member can quickly scan a tracker and associate it with a particular job, part number or any other unique identifier, so that anyone else can access the system, enter the identifier, and instantly ping the location of the tracker.

While finding inventory faster is a great benefit, it may be that the real power of these tracking systems is the way they integrate into production mapping. Since we have tracking devices continuously broadcasting their locations, why not have a server keep a record of the locations and times that are reported? That data can then be plotted by software into a “spaghetti diagram” overlay on your factory floor map, showing exactly where a particular product was at any given time, how it moved there, and how long it sat in any location. Now with the click of a mouse and almost no effort, you can get a true-to-life view of how product is flowing through your factory. Talk about connecting those dots!

These and other technologies are empowering manufacturing teams to become more agile, more productive and safer, a set of goals that are all important and often conflicting with one another. They are also allowing planners and managers within factories to get a clearer, more accurate, and more instantaneous understanding of how their operations are running and where they are headed. These and many other new developments in equipment and software falling under the umbrella of Industry 4.0 are already driving positive change in factories around the world. Considering that the Internet of Things is still, in many ways, in its infancy and will continue to mature in the coming years, the future of fabrication looks bright indeed.