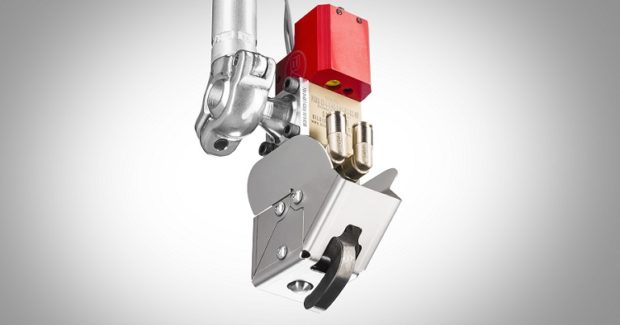

Hot Forming Gripper

Lightweight PSB-20 pneumatic grippers from Bilsing help increase stroke rates in hot forming automotive components with short opening and closing cycles that increase productivity and optional sensors to correct part positioning.

Posted: September 5, 2019

In Booth A-1307, Bilsing Automation North America (Roseville, MI) will showcase their new PSB-20 pneumatic grippers featuring a heat protection shield designed to withstand high temperature environments required for hot forming applications required to produce B-pillar, C-Pillar or Roof frames, for example. The PSB-20 can handle workpiece temperatures of up to 1,000 deg C and come with a self-locking feature that ensures higher production safety and capable of achieve a clamping force of 800 N. These hot forming grippers are manufactured from high strength aluminum and can reach 40 spm. They have a slim profile and flat design, helping to decrease collision risk. Available in a variety of sizes, these lightweight grippers can help to achieve increased stroke rates. They offer short opening and closing cycles for increased productivity. Styles are also offered with optional sensor versions to ensure correct part positioning.

This hot forming series is available in fixed jaw, block jaw, and L-versions – all with either two clamping pins or thin versions with one clamping pin. Depending upon the configuration, both jaws can be dynamic. Various connection choices are also available including lateral ball, lateral pin, back ball connection or STS-tube connection in the back.

Bilsing Automation North America, 20220 Cornillie Drive, Roseville, MI 48066, 586-463-0686, www.bilsing-automation.com.