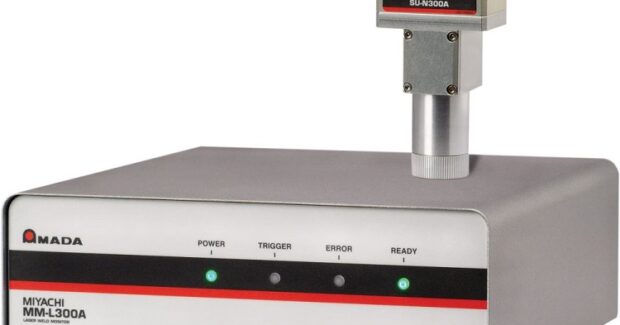

High Resolution Laser Weld Monitor for Spot or Seam Welds

The compact, lightweight MM-L300A Laser Weld Monitor from Amada Miyachi detects gaps between parts, missing parts, over-penetration, incorrect focus and cover gas absence, providing operators feedback on laser weld quality.

Posted: September 23, 2019

In Booth B-37012, Amada Miyachi America, Inc. (Monrovia, CA) will feature their new MM-L300A Laser Weld Monitor, a high resolution, compact unit designed to detect production errors, such as gaps between parts, missing parts, over-penetration, incorrect focus, and cover gas absence, providing operators feedback on laser weld quality. This lightweight monitor supports laser welding technologies for spot or seam welds and is ideal for process development and quality control applications of laser welding. The MM-L300A determines weld success by detecting and recording a thermal signal from the area of laser interaction and provides an output waveform around which limits (max/min or envelope) can be set. Once the limits are set, the unit compares a new weld waveform in real-time to identify good or bad weld. Providing high temporal resolution – down to one microsecond – the MM-L300A with an SU-N300A dedicated thermal sensor enables precision monitoring of both CW and pulsed lasers.

The MM-L300A features easy-to-use software for simple sensor configuration, waveform envelope limit set-up and real-time or saved waveform analysis on Windows® PCs. Plus, with machine-selectable setup schedules, the unit can monitor different welding conditions. For process design flexibility, this approximately 7 lb (3 kg) system reduces set-up space when integrated into a production line, and the sensor mounts either on the optical axis of the laser or in an off-axis position.

Amada Miyachi America, Inc., 1820 South Myrtle Avenue, Monrovia, CA 91016, 626-303-5676, Fax: 626-599-9636, www.amadamiyachi.com.