When Less is More: Material Handling

Here is some of the latest automation, robotics and other equipment that can help you optimize flow, reduce costs by decreasing the number of times employees touch the material, shorten the time and distance it travels, avoid damage and boost storage capacity.

Posted: August 12, 2019

Robotic Handling of Heavy Parts for Adaptable, Flexible Machining

The RoboCell One from Fastems handles heavy parts weighing up to 176 lb and automates up to two lathes or milling machines of the same type.

How to Get Automation Started Quickly and Cost-Effectively

To maximize efficiency, increase profits, address labor shortages and improve operator safety, all components in the FastLOAD CR2000 cobot machine tool cell from Acieta are fully integrated for fast delivery and start-up at a low cost.

Meeting the Need to Feed Large Quantities of Bar Stock

Economical Tracer hydrodynamic magazine bar feeders from CNC Indexing are ideal for shops with fixed headstock and Swiss-type CNC lathes that need to hold and feed longer bar stock securely and precisely for long production runs.

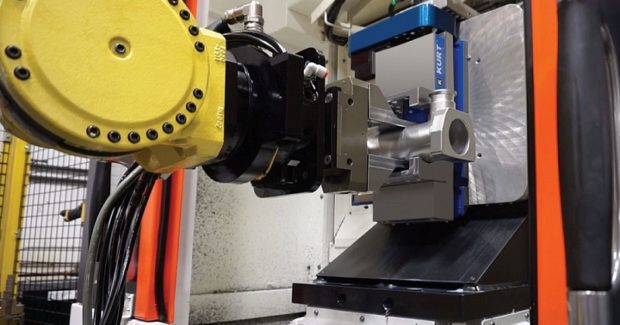

Air Powered Vise Handles Parts in Robotic Machining Cell

For part handling that requires consistent clamping not easily attained by manual operation, the motorized air vise from Kurt delivers robust clamping repeatability, consistent preset clamping force and programmability of the vise opening if desired.

Increase Barfeed Productivity with a Three-Feedtube Cartridge

For use with Swiss-style CNC screw machines, the Multi Mini Rhinobar hydrodynamic barfeed from Lexair makes multiple stock diameter indexing simple and fast by combining three feedtubes inside a single aluminum barrel.

Metal Handling is Only as Good as its EOAT

End-of Arm Tooling systems from Piab optimize the precision handling of difficult loads, from repeatable blank transfers and placements in press stamping to vertical and horizontal pick-and-placing of spools, machined parts, pipe, large gears, barrels and more.

Stationary, Mobile and Portable Handling of Sheet Metal and Coil Storage

Slit Coil Storage Racks and Adjustable Pin Tables from Rack Engineering address high weight storage challenges and meet the exact sizing requirements of users.

Next-Generation Teachable Cobots Improve Machine Tending and More

OB7-Max 8 and OB7-Max 12 seven-axis smart collaborative robots from Productive Robotics add an enhanced human sense of vision that provides unique, flexible and cost-effective capabilities not currently available in the market.

Powered Conveyors for Automated Orbital Wrapping System

Powered conveyors for the fully automated TAB Wrapper Tornado Perfect Storm wrapping system automatically advance the pallet load into and through the wrapping ring smoothly and hands-free to support worker safety and speed the wrapping process.