When Production Organizes Itself

Fully automated Industry 4.0 systems from KASTO create an intelligent factory that continually monitors and optimizes itself, produces higher parts, eliminates operating errors, ensuring a good competitive position and heightened customer satisfaction.

Posted: July 16, 2019

Digitalization and networking are rapidly gaining ground in storage and sawing technologies used in the steel trade, the automotive and supplier industry, and in mechanical and plant engineering, where customers demand greater manufacturing flexibility: from batch sizes of one item to large volume production, using more varieties of materials and sizes, with increasing quality standards and continuous pressure to cut costs. Manual and mutually-isolated fabrication processes are giving way to a continuously-controlled, intelligent material flow, where all components involved communicate autonomously with each other in an Industry 4.0 environment – machines, factories, goods and carriers are connected via the Internet of Things (IoT) and communicate with each other using intelligent sensor systems that provide up-to-date status information in real-time. All process-relevant data is recorded and analyzed, enabling users to optimize their entire value chain in a decentralized, autonomous and demand-oriented manner.

The route from raw material to the finished product becomes shorter, more flexible, resource-saving and cost-efficient – and it starts with storage. Metalworking shops increasingly rely on fully automated storage systems for long goods, instead of the old manual methods of widespread floor and cantilever arm storage. Automated systems provide significantly higher storage density, fast access times and maximum stock transparency. Moreover, sawing operations – often the first processing station after goods have been removed from storage – are increasingly unmanned, with sawing machines seamlessly connected to the raw material warehouse and supplied with the required materials using manipulators and conveyor technology. The sawing process itself runs autonomously if the machine is properly equipped, resulting in a highly-efficient, fully integrated and continuous material flow through an intelligent factory.

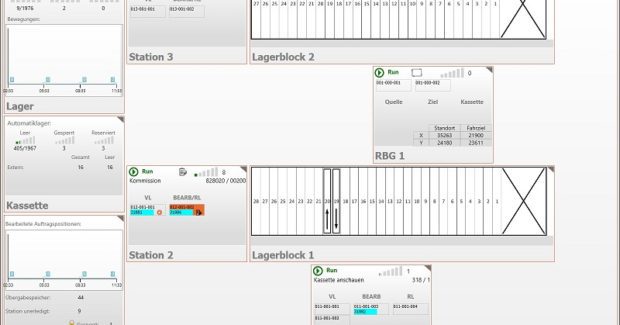

All of the storage, handling, sawing, marking, palletizing and bundling processes in Industry 4.0 storage-sawing-robot systems from KASTO Maschinenbau GmbH & Co. KG (Achern, Germany) are fully automated, from the raw material to the commissioning of the cut parts. Problem-free communication is achieved through integrated control systems and suitable interfaces so allow all of the components involved to “speak the same language.” For example, the modular KASTOlogic warehouse management system (WMS) is specially tailored to the fabrication requirements of long goods and sheet metal storage. This WMS maps all the processes between materials receipt and dispatch clearly and transparently for efficient control of the entire material flow, including the warehouse, the associated conveyor technology and the processing machines with their material handling.

The software optimizes processes in and around the warehouse, making intralogistics faster, more reliable and more efficient. The travel routes of storage and retrieval machines are more efficient by avoiding empty runs and placing frequently-used items closer to storage and retrieval stations than others that are required very often. KASTOlogic functionally manages orders, batches, remaining parts and first cuts, providing a permanent inventory that allows a shop to flexibly apply different in-out strategies and picking principles. Comprehensive statistics and analysis tools monitor utilization of the entire system and individual components to fully exploit the potential of intralogistics, avoiding superfluous routes and unnecessary waiting times. Possible changes can be simulated in advance and tested without risk. With customized interfaces ranging from SAP, Infor and Microsoft Dynamics to customer-specific software systems, this WMS can easily connect to a higher-level host system within the company, as can individual KASTO machine control systems, creating a uniform communication structure that significantly increases transparency and efficiency.

Users can easily control all of the orders, and the data collected and recorded in the warehouses and sawing machines can be comprehensively analyzed and utilized for continuous tracking of specific goods and workpieces and the uniform utilization of the machine park, with short non-productive times, improved quality control and the enhanced planning of maintenance measures. Even remnant lengths and warehouse stocks can be sustainably optimized with relevant information, significantly reducing production costs. Manually-operated warehouses can also be managed with KASTOlogic by using the KASTOmobile app. It is suitable for all Android mobile devices and enables users to transmit all information on storage and relocation, picking and shipping and inventory information to the WMS via smartphone or tablet. A KASTO handheld device handles these tasks using an easy-to-read display, robust housing and integrated barcode scanner. For transparency and traceability, the employee simply uses this device to collect the required order item information, which is then wirelessly transmitted to the management system. The “Pick-by-Crane” system can also be effortlessly implemented with KASTOmobile: users can use the app to control a networked indoor crane, which then carries out the desired storage and retrieval procedures with the aid of the relevant coordinates.

The KASTOsort robot link automates production processes upstream and downstream of the sawing process and integrates these into a uniformly-controlled material flow. Industrial robots not only remove the saw cuts independently, they also perform deburring, chamfering, centring, threading, marking, printing, sorting, stacking and picking. This robotic system can be further integrated with a container management or driverless transport system. Depending on the shop’s requirements, robot controls can be integrated into the saw controls, the KASTOlogic WMS or an existing ERP system, enabling users to also control and monitor this work step with a single interface and benefit from a perfectly harmonized process chain. Mobile devices are gaining use in the clear visualization of sawing machines with the KASTOapp, which displays the status of all the networked machines equipped with SmartControl, AdvancedControl, ProControl or ExpertControl systems. Users can see the name, machine number and type of each saw at a glance.

If a saw is running in automated mode, the KASTOapp can access the information stored in its machine control program, giving users exact information on all the relevant parameters, such as the article, cut length, target and actual quantity, feed rate and cutting speed. If a malfunction occurs, the app displays a graphic visualization of the relevant error message so that users can react quickly and reduce downtimes to a minimum. The VisualAssistance system goes one step further, using augmented reality to simplify the remote maintenance of machines and systems. An interactive app for tablets, smartphones and smart glasses lies at the heart of this system – and customers can use it to connect with KASTO service specialists via video and audio streams. Users and service technicians see the same view in real time, greatly facilitating mutual understanding and helping to quickly identify individual plant components and any faults that may occur.

With this app, service techs can provide visual assistance and display markers in live video. Using augmented reality, the customer sees all the necessary information on his display while carrying out on-site maintenance or repair work on the saw or storage system – and if he uses data goggles (smart glasses), his hands are free to make his task even easier. Service engineers are on-site virtually to advise and help shop employees as required, removing the need for complex training courses involving costly travel. This Industry 4.0 system can make manufacturing processes more flexible and efficient, improve machine utilization, shorten non-productive times, lower maintenance costs and production costs. Since the intelligent factory continually monitors and optimizes itself, the quality of manufactured parts is consistently high and operating errors are virtually eliminated, ensuring a good competitive position and heightened customer satisfaction.

KASTO Maschinenbau GmbH & Co. KG, Industriestr. 14, 77855 Achern, Germany, +49 (0) 7841 61-0, Fax: +49 (0) 7841 61-111, [email protected], www.kasto.com.

KASTO, Inc., 3002 Venture Court, Export, PA 15632-8949, 724-325-5600, www.kasto.com.