The Practical Impact of Industry 4.0 – Part 2: Automatic Manufacturing

Last time we saw how Industry 4.0 uses automated software to control and simplify the flow of information and tasks. Now let’s explore how it uses automated hardware to control and simplify the flow of materials and goods.

Posted: July 30, 2019

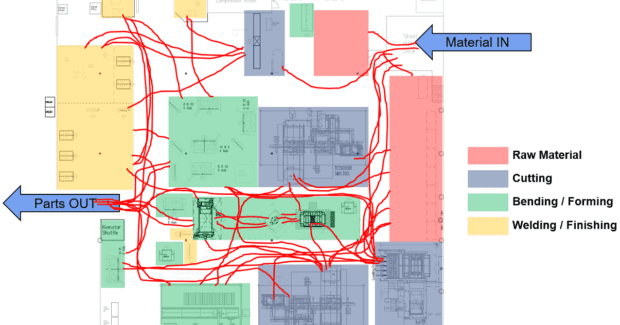

This series examines how the primary components of Industry 4.0 can have a positive impact on your workplace. “Part 1: The Digitalization of Processes” (The Cutting Edge, June-July 2019) focused on software and communications technology – the backbone of Industry 4.0 – and how they speed up operations by enabling shops to work smarter, not harder, building and improving connections between “people processes” and fulfilling opportunities to connect and automate everywhere throughout the business. As a manufacturing template, Industry 4.0 provides a lot of tools for managing the flow of work and information. But in an industrial setting, we must also manage the flow of materials and products. If digitalization of processes gives people greater speed and agility in managing their tasks, automation of physical work enhances their strength.

For example, a sheet or billet of raw material might weigh a few hundred pounds, but with the assistance of a crane and hoist, a single person can manage this heavy load. The crane acts as an amplifier: It increases the work that the person moving the material can do several times over. Now take that crane and give it some basic intelligence so that the operator doesn’t need to constantly manipulate controls, and you have multiplied the power of the person supervising that operation several times more. Replacing physical labor with machine force has always been foremost on the minds of people whose business is making things: How can I make it faster, at a more consistent quality, for a lower price? All sorts of machines require the input of raw material to generate the output of parts that have value, so an obvious step is to automate the physical task of picking up a piece of raw material and loading it into a machine.

Thinking this logic through a bit further: How does the raw material get to the loading device? If someone is physically pulling it from inventory and then delivering it to a loading stack, that process could be automated too. A rack system for raw material that has a retrieval elevator capable of moving each rack independently can deliver different raw materials needed for production to a loading device on demand. This means operators don’t have to worry about keeping machines fed with material, so they can focus on the other tasks that need human attention. Material storage and retrieval systems for fabrication equipment could be said to come in two general styles: “Cellular” storage solutions, in which a small to mid-size material inventory and retrieval system is dedicated to serving one or two fabrication machines, and “logistics center” solutions, where a very large material inventory is connected to numerous machines and manufacturing steps.

Because the number of machines is limited in a cellular automation system, the retrieval elevator can react quickly to frequent requests for material. These systems work well in flexible production environments, where lot sizes are small and material changes are frequent. Logistics center systems, on the other hand, have a single elevator and material storage for many manufacturing processes. These larger systems demonstrate very good efficiency in high-volume production situations, where lot sizes are large and material changes occur less often, so a single elevator has the capacity to deliver material and products wherever needed throughout the course of the working shift. Having all the required material to meet the factory’s turn-over in one storage location simplifies inventory management, too.

Of course, all of this input must go somewhere, and in most manufacturing situations it must go to a very specific destination within a well-defined window of time. Now we find that having a faster material loading process will automatically necessitate a faster unloading process to avoid a throughput-diminishing bottleneck. Just like we can use a smart pick-and-place device to provide raw material as needed, a similar device on the output side of the machine can take away processed parts. However, when it comes to sheet metal processing, this output can be a little tricky to manage: A sheet-cutting machine can output many different parts from a single sheet of material, and the parts will generally be surrounded by a frame of waste material. These diverse parts must be sorted and stacked in order to be used at the next manufacturing step, and the scrap metal must be separated and disposed of. For this reason, unloading automation systems have been developed with many different functions.

At the simplest level, unloading automation simply removes parts and scrap from the worktable of a machine so that the machine can keep working. The parts and scrap are delivered to a table or pallet offline from the machine, where they can then be sorted and stacked by people. In many cases, unloading systems can take this process further by making it possible to automate the separation and stacking of finished parts and scrap. Where fully-automatic separation is impractical, it pays to put some thought into the most efficient way for people to manage the sorting process: hand tools to make the process easier (even something as simple as a suction cup on a stick), jib cranes and vacuum hoists to move large products, ball-transfer or conveyor tables to improve ergonomics and safety, i.e., a lot of small ways to improve the task of de-nesting can reap big rewards in productivity.

The other big piece of the physical effort pie-chart on a factory floor is equipment setup. Many machines – press brakes, for example – require hard tooling to be switched-out between different jobs. Automatic tool-changing devices not only speed-up that changeover process, they can also reduce fatigue and strain for the equipment operators and eliminate potential safety hazards. Even machines like lasers and waterjets that do not require hard tooling changes still typically require some mechanical setup adjustments from one order to the next. Sheet cutting machines often use a nozzle to direct the cutting medium, and these nozzles often must vary in shape or aperture size when processing different materials. Machine functions that can automate these setup steps are power multipliers for the operator, just like material handling systems: A laser machine that can change nozzles and calibrate itself when switching jobs needs less attention during production, freeing up personnel capacity.

The underlying theme of Industry 4.0 is really about handing manufacturing people larger and larger levers with which to drive production. Use automated software to control and simplify the flow of information and tasks; use automated hardware to control and simplify the flow of materials and goods. The road to the fully-automatic Smart Factory is built on intelligent machinery that turns the operator on the factory floor into a literal superhero: Able to move entire mountains of material with a wave of the hand and a flick of the fingers.