The Power of Additive Machining

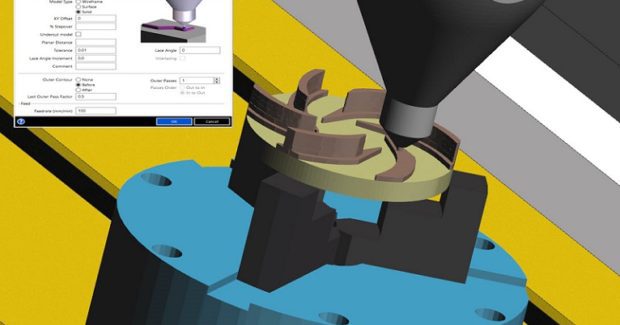

The Additive Machining module in Edgecam 2019 R1 software from Vero accurately guides a laser as it deposits material to build a shape using direct energy deposition, then uses advanced rotary and five-axis milling cycles to finish the final shape.

Posted: July 2, 2019

To meet the increase in hybrid manufacturing, the Additive Machining module in Edgecam 2019 R1 software from Vero (Forest Lake, MN) supports the direct energy deposition (DED) method by providing a dedicated manufacturing cycle that accurately guides a laser as it deposits material to form a shape. After that, the shape is machined using Edgecam milling cycles to create the final component. R1 offers full ToolStore support for Additive Manufacturing and shapes can be built using almost any milling cycle, including advanced functions such as rotary and five-axis simultaneous machining. Edgecam brand manager John Buehler explained how the new Additive Lace cycle can construct geometry on a layer-by-layer basis, depositing a continuous molten bead of material that adheres to the parent material: “Using the same intuitive dialog interface as all other Edgecam cycles, Additive Lace not only works with various CAD entities, but also enables the user to determine numerous control types, such as lace angle, amount of finish passes, and undercut mode.”

Overall, Edgecam 2019 R1 includes around 30 individual enhancements, including:

- Performance Improvements. To generate quicker toolpaths that reduce production costs, R1 introduces three performance-boosting enhancements to its machining engine, benefiting both turning and milling operations. Regeneration time has been reduced by around 20 percent when editing Move Angular/Index commands. “The Waveform machining algorithm further reduces processing time,” said Buehler. “Previously, performance bottlenecks were detected when small stepovers were used, or on components with narrow channels and heavily curved regions. Users will notice average time savings between 15 percent and 60 percent, depending on the complexity of the component and its cycle parameters.” Improvements in the way the machining engine generates data make machining large complex components considerably quicker by using software that calculates prismatic geometry within the toolpath.

- New Parting Off Cycle. A Parting Off cycle for turning operations satisfies a high demand for a single cycle to not only perform the parting off toolpath, but also to deburr the back edge during the operation. “Like all other turning cycles, Parting Off offers extended help through dialog pictures and is sensitive to the current stock position,” noted Buehler.

- Finish Turning Cycle Support for CoroTurn® Prime Inserts. A new Up-Cutting function has been added to the Finish turning cycle for high productivity finishing achieved with Sandvik Coromant CoroTurn Prime tools and inserts. Located alongside the Down-Cut modifier, Up-Cutting reverses the direction of the toolpath to utilize the Prime insert geometry. The cycle feedrate can also be expressed using the ‘Chip Thickness’ modifier, as well as in the traditional format of feed per revolution.

- Multiple User Experience Turning Enhancements. Found in the Rough Turn cycle, the Stock Runout function gives greater toolpath control when exiting the cut. The inclusion of Runout Angle and Runout Length means toolpaths can be trimmed to user-specific demands. “Both the Thread Turning and Finish Groove cycles benefit from functionality found in other turning commands. A Safe Distance modifier added to the Thread Turning cycles provides more accurate control at the start position of a threading toolpath,” stated Buehler. “Finish Groove toolpaths are more tightly controlled with new Start and End Extension modifiers.” The Spindle Set-up function for multi-spindle lathes now includes Main and Sub spindle C Angle positions to guarantee no collisions during the parts transfer command.

- Numerous Edgecam Inspect Enhancements. Although Edgecam Inspect is less than two years old, it continues to grow fast, and Edgecam 2019 R1 introduces 13 new enhancements to it. “Firstly, the mathematical brain behind the product is being switched to use the PCDMIS fit libraries supplied by our parent company, Hexagon,” explained Buehler. “All Geometry Fit calculations, such as measurement deviations and GD&T values, now use a higher level of certified and approved algorithms. And we’ve introduced more customization. Where users once had to accept the standard Measurement Report, they can now develop their own software plugins to personalize it, along with developing their own probing Canned Cycles, usually in Renishaw or M&H format.” Probing features are managed more easily, as all commands are automatically created on separate layers. “Also, where either the solid model geometry is incorrect, or the model isn’t available, the new manual feature means it’s still possible to inspect a region,” added Buehler. Specific Probing features now work with rotary solid faces and the feedback can also include evaluation of Axis Deflection. “The final enhancement to this area provides two new output variations in the Work Offset function: Type and Axes. These give greater control and a more detailed inspection routine, while communicating to the machine tool via the NC Gateway,” said Buehler.

- Hole Cycle Extra Collision Detection. The Hole Cycle has additional collision checking. While stringent detection has been in place for a number of releases – such as a toolpath being re-directed to avoid a clamp – R1 checks if a hole is obstructed by any part of a fixture. “Where such a collision exists, the system removes the drill position and alerts the user,” noted Buehler.

- Chamfering Cycle Gouge Checking. Gouge Check Gap added to the Chamfering Cycle gives even stricter control over the toolpath. Specifically, neighboring features that could potentially come into contact with the flute of the taper tool can now be excluded.

- Extended CAD Format. R1 supports the latest version of all CAD files. “Focusing on a few formats, users will notice, for instance, support for SpaceClaim 19 (ACIS V28), Parasolid version 30.1.247, Inventor 2019, and Creo 5.0. All other CAD formats will be catered for when a newer version becomes available,” explained Buehler. “It’s particularly exciting that, regardless of which license a user has, they’ll be able to load all Designer files – *.v_t and *.vdf extensions – from our latest CAD package, featuring direct modeling technology. This is a major boost for shops who haven’t sampled the power of Solid Machinist capabilities.”

Vero (Edgecam), 25 North Lake Street, Suite 220, Forest Lake, MN 55025, 866-334-3226, www.edgecam.com/contactedgecam.