Scalable 3D Printing Systems Meet Evolving Business Demands

Modular production platforms from 3D Systems help shops evolve and grow by accelerating their time-to-market with ultra-fast production of highly accurate and repeatable parts, without regard to a minimum order quantity.

Posted: July 1, 2019

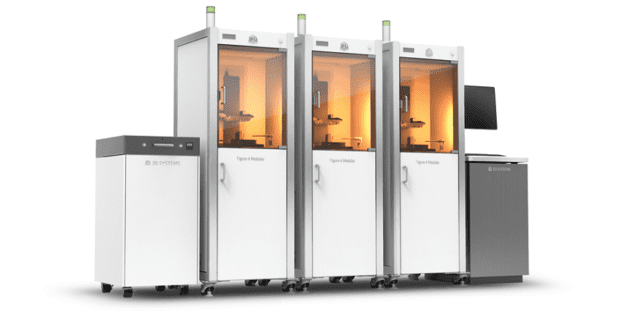

The Figure 4® Modular flexible production system from 3D Systems Corporation (Rock Hill, SC) has configurations designed to allow users to grow as their needs and businesses require. This digital light printing (DLP) production system is capable of producing parts with high surface quality and fidelity. The Figure 4 platform helps accelerate time-to-market with ultra-fast production (up to 100 mm/hr) and six sigma accuracy and repeatability that enables manufacturers to quickly iterate designs or produce end-use parts without regard to a minimum order quantity. This truly scalable system meets the needs of various production environments, from standalone units to automated factory solutions. The Figure 4 platform includes three models:

- Figure 4 Standaloneis an affordable, industrial-grade single engine system for low-volume production and rapid same-day prototyping. Ideal for small design shops and OEMs, it provides industry-leading durability economical print volume at the lowest cost compared to other printers in its class.

- Figure 4 Modularprovides an upgradable and cost effective direct 3D production system that can include automated materials-handling and centralized post-processing. Manufacturers can scale Figure 4 Modular as their production needs expand, including up to 24 print engines. Powered by 3D Sprint® software, each engine can run different materials and jobs simultaneously as part of a single, high-throughput line. With a low cost of entry (starting at $49,900, including controller and single printer engine) and automation options that include job management and queuing, material delivery, and centralized post-processing, shops can reduce demand on manufacturing resources and lower total cost of operation. Additionally, it is 3D Connect™-capable, allowing remote services via 3D Connect Service, which automatically notifies the 3D Systems service team when an alert condition occurs.

- Figure 4 Productionis a completely customizable and automated tool-less manufacturing system that packages the design flexibility of additive manufacturing in configurable, in-line production modules. Automated material delivery and integrated post-processing reduce labor requirements, increase productivity and lower total cost of operation.

Users are already realizing the benefits of this flexible production platform: sporting goods manufacturer Decathlon (Villeneuve d’Ascq, France), service bureau Midwest Prototyping (Blue Mounds, WI), and product design and contract manufacturer D&K Engineering (San Diego, CA) have experienced great success with the printer. “We design and produce innovative sporting goods for our customers globally in order to make sports accessible,” said Julien Guillen, the AM leader at Decathlon. “By incorporating the Figure 4 Modular system into our design and development cycle, we have the potential for much higher productivity with a wider variety of material choices. For example, using an existing desktop SLA solution, it would take 29 hours to produce our tensile test for material validation. With the Figure 4 Modular using the Figure 4 TOUGH-GRY 10 material, we were able to print the same quantity in 90 minutes – more than 19X faster. With features like automated material feed and job management, we are able to improve productivity and reduce costs associated with labor.”

“The combination of Figure 4 Modular and the Figure 4 TOUGH-GRY 15 material allows us to produce very accurate, high fidelity parts in a matter of hours, as compared to overnight with traditional processes,” explained Steve Grundahl, the president and chief executive officer of Midwest Prototyping. “With its automated material feed and job management, the system is very easy to use, and one of the fastest technologies we have in-house. We can now build high fidelity parts with superior surface quality, and offer same-day delivery of parts with different materials. Our customers have been very happy with the part quality we delivered.”

“The quality of the final parts we are able to produce using the Figure 4 Modular is excellent,” added Chris Nicoll, the prototype lab manager at D&K Engineering. “Many of our engineers have commented ‘this looks as good as a molded part’ due to the excellent model conformity, surface finish, and physical properties. We can instantaneously create prototype parts, and small quantities of production parts, with injection-molded quality. This flexible system is replacing other traditional technologies we currently use, decreasing our development cycle, shortening time-to-market, and dramatically increasing our productivity to better serve our customers.”

For plastic 3D printing applications, new DLP and SLS materials for this system include Figure 4 FLEX-BLK 10, a flexible material for the production of exceptionally durable propylene-like black parts. This material is ideal for functional assemblies and prototypes, master patterns for RTV/silicone molding, short-run production, and concept and marketing models. It joins a portfolio of materials that includes Figure 4 TOUGH-GRY 10, Figure 4 TOUGH-GRY 15, Figure 4 ELAST-BLK 10, and Figure 4 JCAST-GRN 10. Other materials planned for release include:

- Figure 4 TOUGH-BLK 20 (anticipated availability Q3 2019) is an ABS-like black material with industry-leading UV stability and high accuracy for production applications.

- Figure 4 MED-AMB 10 and Figure 4 MED-WHT 10 (anticipated availability Q3 2019) is a transparent amber and a white biocompatible material that is sterilizable and capable of meeting ISO 10993-5 and ISO 10993-10, suitable for use in general medical applications requiring translucency, sterilization, and/or thermal resistance, as well as consumer high temperature applications where rigid function are desirable with transparency or white color properties.

- Figure 4 HI-TEMP-AMB 250 (anticipated availability Q4 2019) is a very high thermal-resistant material (HDT > 250C) for design verification testing, motor enclosures, and low pressure molding/tooling with transparency for flow visualization.

3D Systems also offers DMP Flex 350 and DMP Factory 350 metal 3D printers for volume production of seamless critical components used in aerospace, healthcare, and transportation applications. Both of these printers are engineered for robust, repeatable 24/7 metal part production used in research, application development and job production. The DMP Flex 350 provides efficient production of very dense, pure metal parts. It uses advanced gas flow technology to improve uniform part quality across the entire build area and increase print productivity by 15 percent over previous models for faster time-to-market with lower total cost of operation. The starting price for a DMP Flex 350 is $575K. The DMP platform design enables shops with demanding production environments to scale from the DMP Flex 350 to the DMP Factory 350 as production needs evolve within their factory.

The DMP Factory 350 – developed in partnership with GF Machining Solutions LLC (Lincolnshire, IL) – combines the same features and advantages of the DMP Flex 350 with integrated powder management to build higher quality seamless metal parts up to 500 mm x 500 mm x 500 mm with lower total cost of operation. An in-unit viewing panel enables visual inspection of the ultrasonic sieve to ensure incident-free operation. This 3D printer includes real-time process monitoring via DMP Monitoring and allows users to analyze and optimize parameters for higher quality final parts. The system is comprised of five function-specific modules:

- The Printer Module (PTM) is designed to withstand the rigors of 24/7 production cycles enabling maximum printer uptime and output.

- The Removable Print Module (RPM) is a sealed module for powder and part transport between printer, powder, and transport modules featuring a vacuum chamber to ensure the lowest O2 content enabling high quality 3D printed metal parts. Powder waste is eliminated, as the vacuum chamber guarantees consistent high material quality, sufficient to be re-used to depletion.

- The Powder Management Module (PMM) efficiently de-powders parts on build platforms, automatically recycles unused powder materials, and prepares the RPM for the next build.

- The Transport Module (TRM) enables efficient movement of the RPMs between printer and powder modules – reducing production time.

- The Parking Module (PAM) provides interim storage of RPMs in an inert environment until ready for further progression in the workflow (e.g., stores a fully prepared RPM for its next print job while the PTM is finishing the previous print job).

The modular design of the DMP Factory 500 enables continuous function of all metal 3D printing and powder management modules to maximize uptime, throughput and operational value. The ability for a manufacturer to create a custom solution – matching the number and type of modules required for their production workflow – helps maximize their investment, while the integrated automation minimizes manual processes to reduce total cost of operation. In addition, the DMP Factory 500 system includes seamless data connectivity with all major ERP systems to facilitate supply chain optimization. Its robust additive manufacturing platform is integrated with the System 3R referencing and clamping system. Zero point clamping enables optimal positioning of the build plate, facilitating a quick transition from the 3D printer to post-processing steps. This integrated feature reduces set-up times and provides enhanced flexibility by quickly transitioning the build plate from the additive process and sending it downstream for post-processing, saving significant time and money.

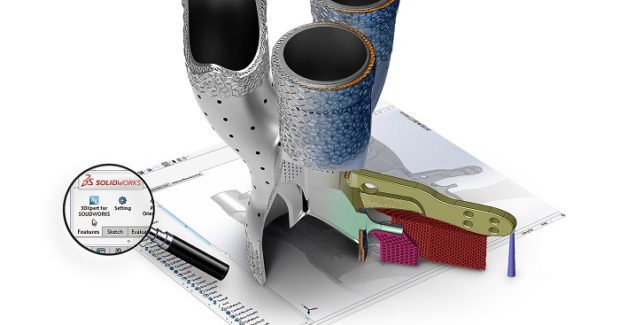

Both the DMP Flex 350 and DMP Factory 350 are integrated with all-in-one 3DXpert™ 14 integrated software that consolidates numerous software solutions into a single integrated system for the entire metal additive manufacturing workflow to dramatically shorten the design-to-manufacturing process. The starting price for a DMP Factory 350 is $763K.

Sharon Tuvia (1982) Ltd. (Nes Ziona, Israel), a full service provider of precision metal parts that uses both subtractive and additive manufacturing operations, purchased a DMP Flex 350 to produce topology-optimized brackets for aerospace work and parts for commercial satellites that require superior quality of the final titanium parts. Their complete DMP Flex 350 system includes the metal 3D printer, 3DXpert software and LaserForm® material. “We challenged titanium parts produced on the DMP Flex 350 with a battery of external tests: evaluating elongation, stress, fatigue, micro-structure analysis, and other factors,” explained Ronen Sharon, the chief executive officer of Sharon Tuvia. “The LaserForm titanium parts performed without parallel and were especially extraordinary when checking for lack of fusion, also called incomplete fusion. Most parts produced using metal 3D printing technologies will reveal lack of fusion. But when we tested these titanium parts, there was absolutely none.”

The shop was also impressed by the improved gas flow technology. “The closed vacuum chamber design not only maximizes powder re-use, but also prevents argon gas bubbles from permeating the part,” noted Sharon. “When parts produced using this technology undergo Hot Isostatic Pressing, the part quality is comparable to forged parts. These results are a must for aerospace parts that need to withstand high amounts of pressure periodically.”

3D Systems has also introduced LaserForm AlSi7Mg0.6 (A), a new aluminum alloy material designed to produce strong, lightweight parts without the need for casting, making it an ideal choice for parts that enable improved fuel efficiency for transportation and other weight-sensitive applications. This aluminum alloy material is compatible with both the DMP Flex and DMP Factory 350. The material’s corrosion resistance, high-thermal conductivity and electrical ductility, as well as good ‘weldability,’ are well suited to such applications as housings, mold inserts, impellers and heat exchangers.

3D Systems Corporation, 333 Three D Systems Circle, Rock Hill, SC 29730, 803-326-3900, www.3dsystems.com.