Real-Time Tracking of Parts Reduces Downtime

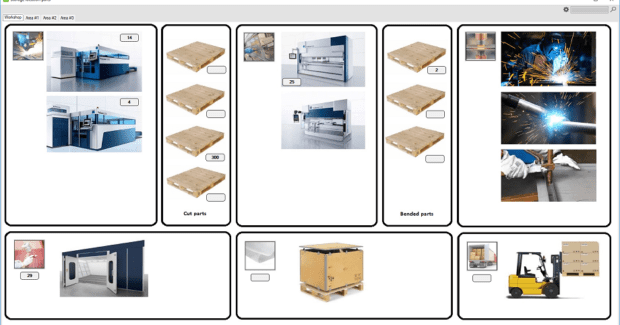

To optimize logistical flows, reduce downtime and improve productivity, WorkPLAN 2019 R1 from Vero Software allows users to model their workshop and localize parts during the manufacturing process in real-time through activity time recordings or operator location declarations.

Posted: July 29, 2019

The problem of real-time tracking of parts throughout the shop is becoming an increasingly urgent need in order to optimize logistical flows, reduce downtime and improve productivity. To meet this challenge, WorkPLAN 2019 R1 project management software from Vero Software, Inc. (Forest Lake, MN) allows users to model their workshop and localize parts during the manufacturing process in real-time through activity time recordings or operator location declarations. Manufacturers no longer want to use independent IT systems, so WorkPLAN 2019 R1 deploys increasingly efficient tools with direct links to other Vero Software applications to create a fully integrated digital channel that regroups all communication and data processing tools to provide key information swiftly and accurately. As well as localizing parts on the shop floor, its wide-ranging features of new and enhanced functionality include a new generation interface with the WorkNC CAM system, automatic recovery of machining times through the machine connection, new graphic representation for project progression, and a new planning display available through touchscreen.

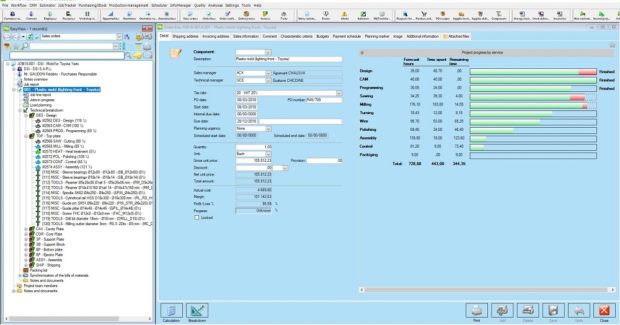

In the interface with WorkNC CAM, a WorkPLAN task number can be readily associated directly in WorkNC. In this way, when postprocessing the WorkNC program, information regarding the task number is transferred to the machine tool. This gives WorkNC users the possibility of optimizing the supervision of their operational workflow and the data exchange between the workshop and different departments. Also, machining times are generated automatically by the machine tool itself and transferred into WorkPLAN through a monitoring tool. WorkPLAN 2019 R1 is easily adaptable, fully meeting the requirements of Industry 4.0: It automatically consolidates different data generated on the shop floor, such as machine status, alarm codes, types of time spent (including adjustment, productive and non-productive), and consolidation of indicators such as OEE and GEE, offering users real-time data interrogation in one single application.

Implementing planning software requires a certain discipline to obtain a clear and precise visual representation as a meaningful support for users. To add value to that philosophy, WorkPLAN 2019 R1 integrates a new project process graphic representation as a standard feature and is based on the current project summary so that users can consult how their projects are progressing at any time, even directly from the home page. The integrated Planning module, along with dedicated workshop touchscreen licenses, have become key tools for users. Other features include:

- Customization of compulsory input fields.

- Estimation of sheet metal requirements, using Radan nesting.

- Improved negotiated component management (purchase/resale).

- Supplier contract management.

- Comment field spell checking.

- New Business Report analysis.

- Risk Management improvements.

Vero Software, Inc., 25 North Lake Street, Suite 220, Forest Lake, MN 55025, 866-334-3226, www.workplan.com, www.verosoftware.com.