Constructing a ‘First Time Right’ Print

Using a digital twin to simulate the build process prior to printing, Additive Manufacturing Process Simulation from Siemens predicts distortion during 3D printing and automatically generates the corrected geometry to compensate for it.

Posted: July 9, 2019

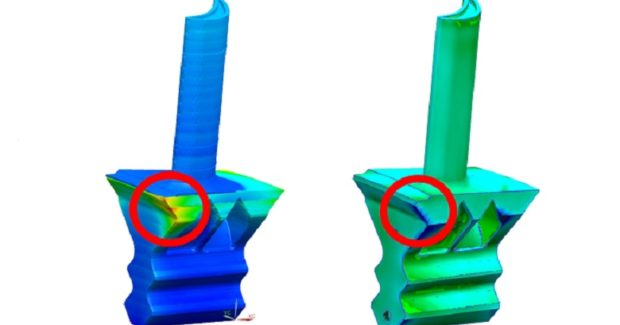

Additive Manufacturing (AM) Process Simulation from Siemens PLM Software (Plano, TX) predicts distortion during 3D printing and is fully integrated into their end-to-end Additive Manufacturing system that assists manufacturers in designing and printing useful parts at scale. AM Process Simulation uses a digital twin to simulate the build process prior to printing, anticipating distortion within the printing process and automatically generating the corrected geometry to compensate for these distortions. This simulation is paramount for constructing a ‘first time right’ print, and necessary for achieving the efficiencies required of a fully industrialized additive manufacturing process. When metal parts are 3D printed, the method used to fuse the layers of the print typically involves heat. As the layers build up, the residual heat can cause parts to warp inside the printer, causing various problems, from structural issues within the part itself to print stoppage. Issues such as these cause many prints to fail and make getting a “first-time-right” print very difficult. Simulation of the printing process can help to alleviate many of these problems.

This process simulation system is integrated into the powder bed fusion process chain in the PLM Software Additive Manufacturing portfolio and is used to predict distortion for metal printing. It provides a guided workflow to the user that allows for the assessment of distortions, the prediction of recoater collisions, prediction of areas of overheating and other important feedback about the print process. AM Process Simulation offers the ability to iterate on a solution between the design and build tray setup steps of the workflow, and the simulation step. This closed feedback loop is possible due to the tightly integrated nature of the Siemens digital innovation platform. The simulation data creates feeds into the digital thread of information, which informs each step of the printing process. This digital backbone enables the system to develop pre-compensated models and, more importantly, to feed those seamlessly back into the model design and manufacturing processes without additional data translation. This high level of integration is what customers need today in order to be successful in industrializing additive manufacturing.

“By combining empirical and computational methods we can increase the accuracy of the simulation process, feeding the digital twin and helping users better predict their real-world print results,” explained Jan Leuridan, the senior vice president for simulation and test solutions at Siemens PLM Software. “Providing corrected geometry and closed loop feedback can ultimately allow them to get better results from their additive manufacturing processes, helping them achieve that first-time-right print and realize innovation with this technology.”

Siemens PLM Software, 5800 Granite Parkway, Suite 600, Plano, TX 75024, 800-498-5351, www.plm.automation.siemens.com.