Blowers for Precise Gas Control in Additive Manufacturing

Side channel blowers from Becker permit precise control of gas flow and removal of contamination within the build chamber of the machine used in selective laser melting operations.

Posted: July 1, 2019

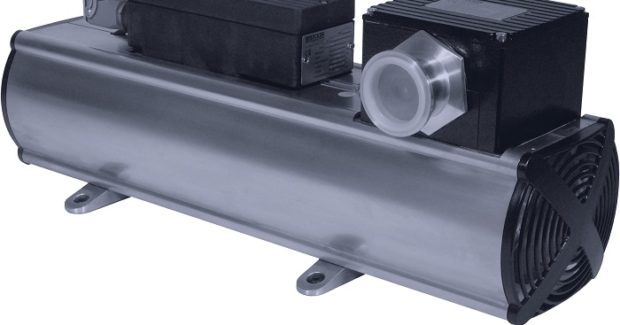

In selective laser melting (SLM) a stable inert gas atmosphere must be ensured within the built chamber of the machine. A specified temperature range is also essential. Only under these conditions can high quality components be produced. It is further necessary to remove metal splash and smoke developing during the melting process. Gebr. Becker GmbH (Wuppertal, Germany) has developed two blower types precisely for these and similar applications. Their gas-tight design permits the precise control of gas flow, as well as the removal of contamination from the process. In combination with gas-tight heat exchangers from Gebr. Becker, these blowers create conditions necessary for exact temperature control of the additive manufacturing process. For plants with a small built chamber, the gas-tight and speed-controlled VASF side channel blowers of size 1.50 are ideal (see Figure 1). Their highly compact construction can be easily integrated in the plant, enabling the flow management of the inert gas in a closed circuit and low energy operation as required.

The gas-tight side channel blower VARIAIR SV 300 is used for larger plants with correspondingly higher volume flows of inert gas (see Figure 2). Here the speed-controlled, energy-efficient drive enables the delivery rate to be adapted to the actual additive manufacturing requirements. Both of these blowers are designed for 24/7 industrial operation and proven worldwide in numerous demanding applications. Due to their gas-tight design, they are suitable for the requirements of additive manufacturing in high-grade atmospheres.

Gebr. Becker GmbH, Hölker Feld 29-31, Wuppertal, Germany 42279, 49 202 697 0, Fax: 49 202 660 855, www.becker-international.com.