Ascent Aerospace Invests in AM

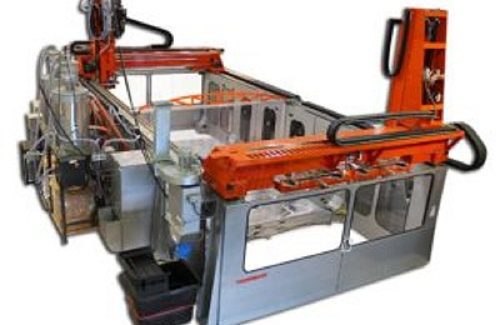

Their LSAM machine from Thermwood will help them commercialize production-ready additive solutions for aerospace tooling.

Posted: July 22, 2019

The use of 3D printing in the aerospace tooling sector has continued to mature over the last several years and is now accelerating in usage. Because of this, Ascent Aerospace (Macomb Township, MI) recently invested in a Large Scale Additive Manufacturing (LSAM) machine from Thermwood Corporation (Dale, IN). Ascent plans to take additive technology to a new level by leveraging their expertise in tooling to commercialize production-ready additive solutions. As a new tooling option for customers, they intend to utilize the LSAM machine to bring tools such as layup molds, masters, trimming/drilling fixtures and vacuum holding fixtures to market faster than ever before. This new additive machine will be co-located with their composite tooling shop, autoclave and clean room in Santa Ana, CA, and will allow them to build targeted tools lighter and more efficiently, providing time and cost savings to global customers.

The LSAM machine will have an industry-leading build area, providing aerospace customers with the opportunity to benefit from large-scale printed composite tooling. By combining this technology with their in-house tooling expertise and heritage engineering, it will be possible to fabricate and deliver fully functional select fixtures and molds with significantly reduced lead-times of a traditional metallic tool. The wide variety of materials that are compatible with the LSAM, such as ABS, Polycarbonate, Nylon, and PESU resins with reinforcing compounds, will further expand the selection of tooling systems that the company will bring to the market.

“Our investment in the LSAM represents the next milestone in our multi-year technology roadmap and realization of expansive efforts studying the benefits of additive manufacturing within the aerospace tooling market,” explained Michael Mahfet, the chief executive officer of Ascent. “This capability positions us to remain a leader in new and innovative tooling solutions, supporting strong collaboration with our customers and supplementing our in-house, vertically integrated design and fabrication capabilities.”