3D Printed High-Strength Aluminum

HRL Laboratories commercialized their 3D printed high-strength aluminum and obtained the first-ever registration of an additive alloy from the Aluminum Association.

Posted: July 8, 2019

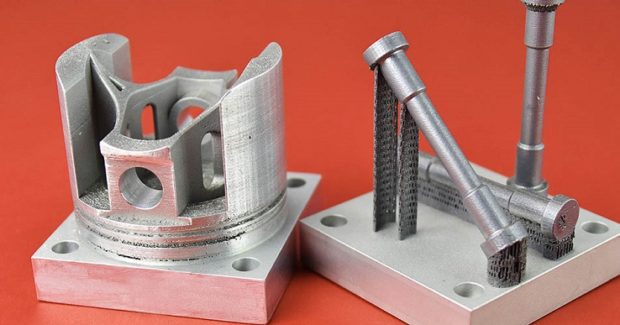

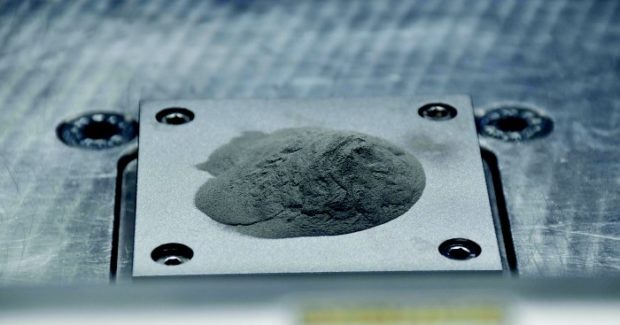

HRL Laboratories, LLC (HRL; Malibu, CA) commercialized their 3D printed high-strength aluminum and obtained the first-ever registration of an additive alloy from The Aluminum Association (Arlington, VA). They were granted registration number 7A77.50 for the aluminum powder used to additively manufacture the alloy, and number 7A77.60L for the printed alloy. The Aluminum Association oversees alloy registration and product standards used throughout industry. Their new additive alloy registration system was launched in February 2019 in response to a growing number of additively manufactured alloys. The first to be registered was the high-strength aluminum from HRL, the first alloy of its kind to be printable. “Essentially, this will connect us to this particular alloy composition forever,” said Hunter Martin, the lead scientist on the HRL team that created the alloy. “These alloy numbers will always be trackable back to us, like a DNA signature. When I first contacted the Aluminum Association about registering our alloy, they did not have a way to register alloys printed from powders, so they decided to create a new system for registration of additively manufactured materials – a first in the materials space.”

“We’re in the process of commercializing this material, which is already in high demand,” added Zak Eckel, another HRL team member. “As we scale up to commercial levels, AA registration validates our product. Companies who want the powder for their 3D printers can ask for its specific number, and it becomes a true commercial alloy.”

HRL Laboratories, LLC, 3011 Malibu Canyon Road, Malibu, CA 90265-4797, 310-317-5000, Fax: 310-317-5483, www.hrl.com.