Welding New Nickel Alloy

Inconel 740H and other new superalloys provide major improvements in mechanical properties and corrosion resistance at elevated temperatures, but they still need careful purging during welding in order to preserve these characteristics.

Posted: June 28, 2019

Significant developments have been made recently and have resulted in the introduction of new nickel alloys that offer major improvements in mechanical properties – not the least of which is Inconel 740H, an alloy offering enhanced resistance to coal ash and therefore of considerable interest to fossil fuel fired boiler manufacturers.1 While these new materials help to expand the use of nickel-based alloys in areas where mechanical properties and corrosion resistance at elevated temperatures are mandatory, the need to maintain strict control during fusion welding remains, in order to preserve these characteristics. Inconel 740H has a higher chromium content than other alloys in this class of materials and, as a consequence, offers significant high temperature corrosion resistance. Notwithstanding this characteristic, all the alloys – and particularly Inconel 740H – are prone to loss of chromium through oxidation during welding unless some form of protection is provided.2, 3

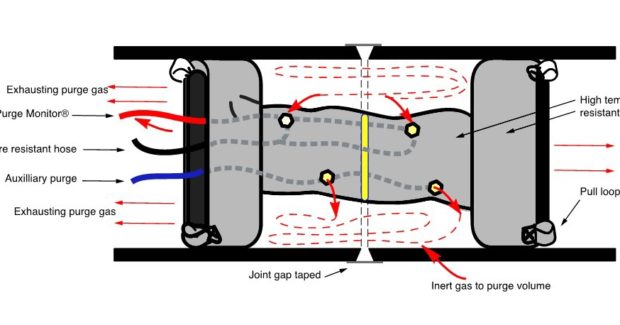

The failure to purge, or failure to purge properly, pipework and boilers will result in a heavily oxidized surface to the weld root inside the cavity with substantially lower corrosion resistance. Even after the completion of the root weld, the weld purge should be continued for several passes to avoid heat tint or discoloration (oxidation) inside the tube or pipe. When using the GTAW process, direct protection of the upper weld deposit can be assured through the inert gas shroud and the use of a trailing shield. The weld root, however, is fully exposed to the atmosphere and oxidation can take place. This means an essential requirement when making butt joints is to provide interior inert gas purging, typically with argon or helium.4 With very small tubes this can usually be achieved through careful continuous gas flow, but this technique is prone to erratic coverage because of turbulence. Isolating the section to be welded by inserting dams on either side of the joint and filling the volume with inert gas is a much better solution.

Attempts have been made to provide dams using paper, card, timber or even polystyrene plugs on the basis of economy but success is erratic – sealing is difficult, contamination is inevitable and effective removal of the debris following welding is difficult. The best solution, and the one now adopted globally by leading fabricators, is to employ commercially available integrated inflatable purging systems (see Figures 1, 2, 3). For adequate protection of nickel alloys during welding, the internal purge atmosphere should have oxygen level reduced to 50 ppm (0.005 percent) or less in order to obtain a root surface with little or no oxide. Control of purge gas oxygen content during welding is clearly an important aspect. Recent development in monitoring instruments (see Figure 3) have led to the introduction of equipment that not only measures oxygen level accurately, but also provides facilities for continuous recording and even overrides the joining process if oxygen levels exceed those pre-set by the operator.

Techniques for measuring oxygen content have been available for decades, but only recently have instruments been developed specifically for welding applications. Users increasingly demand complete absence of discoloration and no loss of corrosion resistance, and this implies purge gas oxygen content to be as low as 20 ppm (0.002 percent). Very few oxygen purge monitors are capable of meeting this sensitivity, but certain instruments cover all of the requirements (see Figure 3).

References

- Characterization of Inconel Alloy 740H for Tube, Pipe and Fittings for Advanced Supercritical CO2 Systems. de Barbadillo et al. 6th International Supercritical CO2 Power Cycles Symposium, March 2018, Pittsburgh, PA.

- Oxidation of Nickel and Cobalt Based Superalloys. Defense Metals Information Center. Battelle Memorial Institute, Columbus, OH. Report 214, March 1, 1965.

- Welding of Nickel Alloys – Part 1 – Job Knowledge 107. The Welding Institute, Cambridge UK.

- Inert Gas Weld Purging of Pipes. M. J. Fletcher. Engineer Live, May 2017.