Touch and Go: Machine Controls

Touchscreen control functions used in smartphones and tablets are now being integrated into CNC machine tool controls to help make programming more intuitive and fast, to navigate quickly and intuitively through long lists, programs, tables and other content.

Posted: June 11, 2019

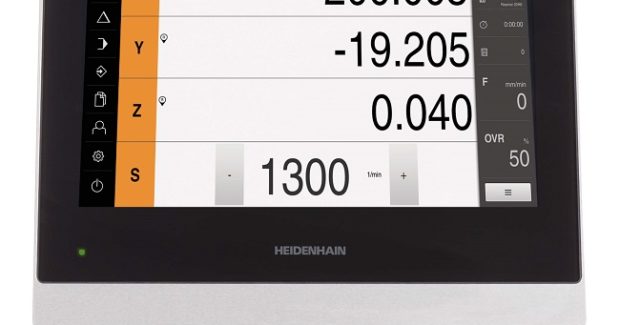

The ND 7013 digital readout (DRO) from Heidenhain Corporation (Schaumburg, IL) promises to provide machinists with significant advantages and even more reliable tools to better utilize their manually-operated machine tools (with up to four axes) than ever before. This DRO replaces the ND 780 and offers an improved user interface and user-friendly touchscreen, along with an improved status bar on the right side of the main screen that provides helpful options for selecting the respective operating status. A quick access menu allows the user to view or select multiple options, such as displaying length and angle values, presets and tools, a stopwatch or calculator, feed rates, an edge finder (in milling mode), as well as an Auxiliary Functions key. An I/O function is available on this new DRO providing additional useful enhancements for supporting machine functions. The changeover from the conventional keyboard to the touchscreen facilitates operation and makes custom settings possible. This also provides increased protection from the ingress of dirt and liquids and thus improves suitability for a workshop environment.

The custom settings are done by configuring keys that are used to switch or control actuators in the machine. Furthermore, with a keystroke, a machinist can call documents (operating instructions, machine manual, tables, etc.) and display them on the screen. If spindle control is activated on the ND 7013 I/O, the user can also define keys for presetting the spindle speed. These custom-defined keys are then included in an OEM bar that can be dragged into the screen, if required.

Heidenhain also provides the POSITIP 8016 digital readout with touchscreen for manual machine tool applications that has a sturdy machined aluminum housing and promises to add reliability and ease-of-use to its milling, drilling, boring and turning jobs. The PT 8016 DRO has a multitude of functions, including a Taper calculator, Bolt-Hole Pattern routine and Tool Radius Compensator. This DRO also includes distance-to-go modes in both absolute and incremental. It can control of up to three NC analog, point-to-point axes and a spindle with the PT 8016 ACTIVE Version. It features a shop-hardened 12 in color TFT touchscreen for an IP65 front panel and an IP40 back panel. Users can plug-in up to six encoders – either 1Vpp or 11µApp incremental or absolute EnDat 2.2 pure serial. The DRO has storage for up to 100 datums and 100 tool parameters, as well as the capability to create, store and execute programs. The PT 8016 replaces the PT 880 and stands alongside the recently released ND 5023 and ND 7013 to round-out the new family of digital readouts.

Heidenhain also offers the workshop-oriented TNC 640 high performance mill-turn control that uses touch technology to supplement its field-proven cycles and functions, allowing the user to operate the control screen with gestures, similar to smartphones or tablets. Using the TNC 640 touchscreen, the operator navigates quickly and intuitively through long lists, programs, tables and other content through kinetic scrolling that converts the impulse of hand contact into a particular scrolling speed. A short, slow swipe scrolls the screen over a few lines, while a long, fast swipe scrolls it over many lines. The user can stop dynamic scrolling at any time with a short tap, which makes it possible to easily find an NC block, for example, or a tool in long NC programs or tool tables. The user moves the programming and 3D test graphics directly on the screen dynamically, smoothly and without jerks. The desired graphic view can be adjusted very conveniently by touch. The user can also use touch gestures to zoom in for details and out again, as well as move or rotate graphics.

The minimum requirement for NC Software version is 340 59x-07 SP2. The hardware enabling touch control are the MC8532 main computer and the BF 860 color flat-panel. These units come without any hardware keys because they are designed for touch operation. The MC 8532 features a 19 in touchscreen, an Intel Core i7-7-3 processor with 1.7 GHz on SSDR and 4GB RAM memory. The BF 860 offers 4 USB ports. The TE 745 (FS) remains unchanged and does not to be upgraded with the hardware. In that way, the operation of the TNC 640 remains familiar to existing TNC 640 users. The Connected Machining, Dynamic Efficiency, and Dynamic Precision solutions packages in these systems continue to expand.

Heidenhain Corporation, 333 East State Parkway, Schaumburg, IL 60173, 847-884-4761, www.heidenhain.us.