Remote Monitoring of CNC Machines from Handheld Device

Users of the Integrated Machine Analytics mobile app from Mitsubishi Electric Automation can do real-time monitoring and analysis of CNC functions on all MTConnect-compliant CNC machine tools in their facility to keep production on schedule and eliminate potential issues.

Posted: June 3, 2019

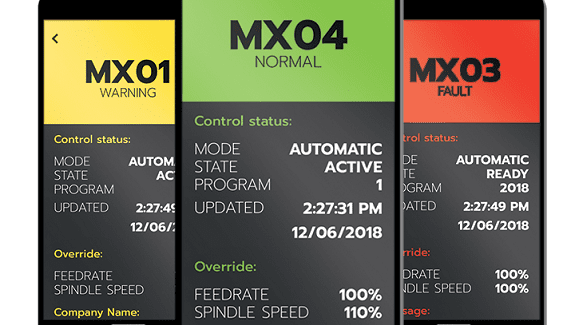

The release of the Integrated Machine Analytics (IMA)™ mobile app from Mitsubishi Electric Automation, Inc. (Vernon Hills, IL) allows users to monitor their CNC machine tools through MTConnect®, an open standard that enables universal connectivity. The IMA app is designed for Mitsubishi Electric machines, but will work for any MTConnect-compliant CNC. It offers real-time monitoring and analysis of CNC functions and will notify the user when changes or anomalies are detected. If users have multiple CNC machines in their facility with an MTConnect-compliant adapter, they can all be monitored through the app simultaneously so that users can ensure projects are staying on schedule and eliminate potential issues before they become significant. “This mobile app is a way for shops to take their first steps towards full Industrial Internet of Things integration,” said Justin Kueker, the business development manager at Mitsubishi Electric Automation. “They can enable push notifications to keep tabs on their machines at all times, especially for significant events like machine warnings or alarms.”

Business owners, engineering or maintenance managers, facility or operations supervisors and others can use this app for machine monitoring purposes to improve their overall equipment effectiveness (OEE). Machine tool dealers may also use the app as another value-added offering for their customers and separate themselves from competing vendors.

Machine tool programmers and engineers that utilize GoProbe macros from Renishaw Inc. (West Dundee, IL) can save significant time and labor by using Interactive Cycle Insertion screens on the M8 Series of CNC controls from Mitsubishi Electric Automation. Interactive Cycle Insertion is an icon-based programming method that integrates GoProbe macros directly into the CNC control so that engineers can choose and customize cycles or features directly into their G-code program through an edit screen. This reduces programming time and potential for human error because programmers no longer have to hand-type the G-code into the control. This system is specifically applicable for tool and workpiece measurement. “With newly created Renishaw GUI screens used in the M8 CNC Series Interactive Cycle Insertion function, probing cycles become more user friendly,” noted Matthew Bascue, a mechatronics engineer at Mitsubishi Electric Automation.

“Probing is an established practice for maximizing efficiency, quality, capability, and accuracy of machine tools,” added Dave Bozich, the vice president of operations at Renishaw. “Our probes can reduce set-up times by up to 90 percent and improve process control. Standard routines built into modern CNC controls simplify the integration of probing cycles. These routines, when combined with a CAD interface, streamline the simulation of measurement functions.” Users looking to acquire a new Renishaw probe can do so with the knowledge that it will integrate into M8 Series CNC Controls.

For more information, look at other advances in the machine monitoring and also subscribe to F&M.

Mitsubishi Electric Automation, Inc., 500 Corporate Woods Parkway, Vernon Hills, IL 60061, 847-478-2100, us.mitsubishielectric.com.