Open Automation Standards Simplify Motion Control Machine Programming

Using software standards from PLCopen, engineers can quickly and efficiently implement complex motion and machine control in high speed multi-axis machining and other industrial automation applications.

Posted: June 3, 2019

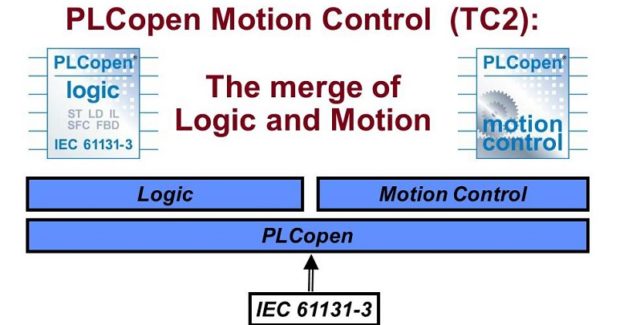

Software standards are essential to achieve competitive manufacturing by leveraging the benefits of Industry 4.0, Smart Manufacturing and the Industrial Internet of Things (IIoT). With the growing need for specialized machines to achieve goals of flexibility and make-to-order manufacturing, it is important for engineers to have the programming capabilities provided by vendors that conform to software standards from PLCopen (Gorinchem, The Netherlands), which can quickly and efficiently implement complex motion and machine control in applications such as high speed multi-axis machining. PLCopen vendor member companies have been committed to developing open industrial automation software standards for more than 25 years to increase functionality while reducing engineering, training, operations, and maintenance costs. These standards are valuable in a wide range of applications, from large controllers to embedded devices, with certified function blocks that perform as defined in open specifications and are only available from member companies to insure function and quality for more efficient engineering, faster start-ups and easier service.

For more information, look at other advances in the smart factory and also subscribe to F&M.

PLCopen, PO Box 3009, 4200 EA Gorinchem, The Netherlands, +31 (0) 183 660261, Fax: +31 (0) 183 664821, [email protected], www.PLCopen.org.