Modular Die Cushion System Extends the Life of Deep-Drawing Dies

The Modular Die Cushion System from Moog improves process reliability, reduces commissioning time, offers flexible layout options for integrating the manifold and requires comparatively little piping to help press rooms lower their maintenance and piping costs.

Posted: June 5, 2019

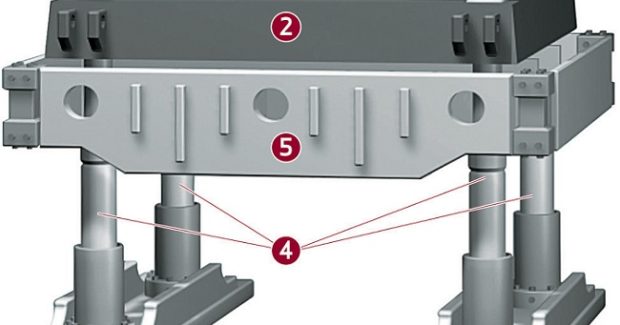

The Modular Die Cushion System from Moog, Inc. (East Aurora, NY) extends the life of deep-drawing dies, improves system reliability and reduces commissioning time for manufacturers. This system includes a main cylinder with integrated position measuring technology, accumulators, a hydraulic power unit and a number of manifolds. It also features software libraries, and the control unit’s hardware components provide a compact, robust hydraulic system that enables highly dynamic control. The manifold flange of the system is integrated directly to the cylinder, where it is connected to the main hydraulic accumulators by a separate adaptor manifold. The system reduces force overshoots that can cause damage in a press and uses customer-specific force profiles to ensure the highest level of accuracy in the drawing process. Maintenance professionals can easily access the system because of the unique mounting of its main components. The system offers flexible layout options for integrating the manifold, and requires comparatively little piping, which helps press rooms lower their maintenance and piping costs.

Moog, Inc., 400 Jamison Road, East Aurora, NY 14052, 716-652-2000, www.moog.com.