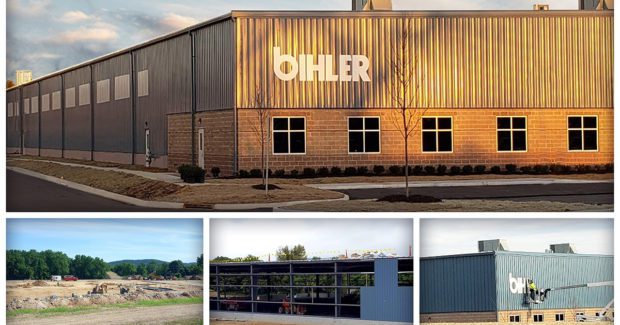

Bihler Expands Capacities

They open a new multi-use operations building next to their two manufacturing plants.

Posted: June 4, 2019

Bihler of America, Inc. (Phillipsburg, NJ) recently opened a new 103,000 sq ft facility in Phillipsburg on a seven-acre corporate campus. the new multi-use operations building is located adjacent to their two existing manufacturing plants. Construction of this new building began in April 2018 and became fully operational in the first quarter of 2019. At present, all three buildings have a combined total of 350,000 sq ft. Driving this expansion was an increased demand in contract manufacturing and automation projects. Before construction began, the company already had several high-volume manufacturing and assembly projects scheduled that require advanced, servo-controlled, high-speed automated machines. The multi-functional facility, built in partnership with IronHill Construction Management, is now fully operational and setup for the production of the 4 Slide-NC, machine service, customer service, spare parts and tooling. It is also the primary manufacturing facility for the BihlerMED line of illumination-based medical devices and high volume disposable battery packs for medical device applications.

“This new building has more than half of its total output capacity committed to already, with plenty of space for the expanded manufacturing needs of our customers,” commented Max Linder, the director of sales and marketing for Bihler of America. The new facility houses dedicated assembly areas for 4 Slide-NC machines, expanding the ability to deliver these highly efficient machines on time for customers. As part of this expansion, the company has begun to add more than 50 people to manage and operate the new facility, in addition to the many roles previously added to existing operations during the last two years. The new building is designed with LED lighting throughout for energy efficiency, with the sustainable energy support of Bihler’s existing solar power field. Currently, the company has three solar installations on their campus, including two rooftop panel arrays and a ground-mounted solar array in an adjacent field.

The layout of the new facility has been designed with optimum flexibility for future growth. “The re-shoring trend that began several years ago remains strong, and general economic indicators predict this ongoing rise in manufacturing will continue,” Linder noted. “Our capabilities for advanced manufacturing, services and equipment have been significantly expanded to accommodate this continuing demand for U.S.-based manufacturing.”