Advanced Machine Control and Part Traceability for the Smart Factory

Ideal for IIoT applications, the NX1 controller, HAWK MV-4000 smart camera, handheld HS-360 DPM reader and MicroHAWK ID-45 reader from Omron integrate machine control and part inspection operations seamlessly with quality management and safety systems.

Posted: June 3, 2019

To help companies meet the customization demands imposed by an increasingly globalized market driven by e-commerce, the compact NX1 controller with OPC UA and SQL connectivity from Omron Automation Americas (Hoffman Estates, IL) includes G-code support, integrates seamlessly with quality management and safety systems and is ideal for IIoT applications. It improves the operations of smart factories at all levels by providing a fast and accurate link between machines and the Industrial Internet of Things for advanced machine control, real-time data traceability, secure information transfer (OPC UA server functionality built-in) and synchronizing of all machine devices with the PLC and Motion Engines. The NX1 can securely transfer data to external network, minimize IT maintenance cost of middleware and PCs, easily set up for direct connection to a host system, and provide reliable international communication protocol for IIoT applications.

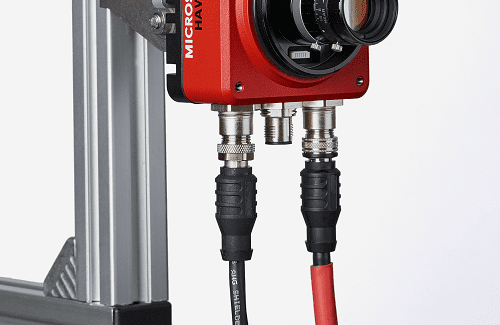

For bar code reading, code verification, inspection, guidance, gauging or a combination of all four operations in the smart factory, Omron offers the powerful, flexible HAWK MV-4000 smart camera with state-of-the-art algorithms that achieve real-time trigger response using a field-programmable gate array (FPGA). The camera’s image-centric user interface with drag-and-drop programming makes it simple to set up. The average operator or technician will appreciate its intuitive AutoVISION user interface (UI) that gets the reading, verification and vision tools ready to read right out of the box. Experts in machine vision will have access to another interface, the FrontRunner, to gain access to the full range of the camera’s potential. With processing capabilities nearly reaching the speeds of more complex PC-based devices, this smart camera is truly in a league of its own. External processing is not necessary to achieve inspection rates ranging from 4,000 to 14,000 parts per minute using the HAWK MV-4000, which is fully accessorized with lens, lights, cables, and mounts.

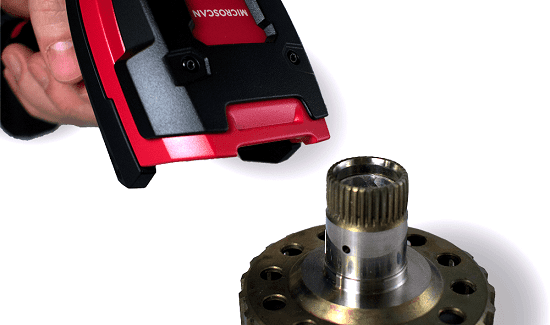

To capture the most challenging direct part marks (DPM) and traceability challenges on all sorts of surfaces, Omron offers the ultra-rugged handheld HS-360 DPM reader and the MicroHAWK ID-45 reader with new and improved lighting configurations. Curved, shiny and irregular substrates are no problems for the advanced X-Mode decoding algorithms inside these two readers. Decoding speed is ultra-fast for dot-peened, laser-etched and ink-jetted codes, regardless of size, density or contrast. Perfect for DPM applications in automotive and heavy industry, the HS-360X demonstrates exceptional durability and shock resistance. Waterproof, dust-proof and capable of withstanding multiple drops to concrete, it’s built to last long in the harshest work environments. A 3100-mAh lithium ion battery coupled with an exclusive on-board battery gauge supports greater efficiency, with 56 percent more scans per charge than competing handhelds.

Operators have increased flexibility and easy setup through WebLinkPC, the force behind the intuitive plug-and-play setup of the MicroHAWK ID-45 reader, which integrates seamlessly into production lines for electronics, medical device manufacturing and other industries. An extensive array of 24 LEDs makes this reader brighter than previous generations. Its true Autofocus and X-Mode technology can decode poorly printed and damaged codes with ease in all sorts of settings, including metal cavities.

For more information, look at other advances in the smart factory and also subscribe to F&M.

Omron Automation Americas, 2895 Greenspoint Parkway, Suite 100, Hoffman Estates, IL, 60169, 847-843-7900, automation.omron.com.