The Practical Impact of Industry 4.0 – Part 1: The Digitalization of Processes

Anytime you must “go and see” something that could be transmitted electronically is an opportunity to connect. Anytime you read data from one place and copy or send it to another is an opportunity to automate. And here’s the great thing: If you are just starting out, it’s pretty easy to take small steps.

Posted: May 29, 2019

It’s clear to everyone working in manufacturing that production technologies are advancing rapidly, similar to almost all technologies in the 21st century. Looking at the current generation of machinery for metal fabrication, significant advances in speed, precision and ease-of-use have been incorporated even compared to similar equipment from just a few years past. The accumulation of all this technological development means that physical production processes around the world are getting faster. While this is every manufacturer’s dream come true (who doesn’t want to do more with less?), the dream can turn into a nightmare when machine processes outpace human processes. When people can’t keep up with equipment, productivity suffers. Even worse, when people start rushing to try and keep up with faster technology, confusion and waste increase while profitability decreases.

The realization that you can’t just keep inserting faster machines into an existing production process while everything else stays the same is one of the driving forces behind digitalization. As machines get faster and the pace of production picks up, the people-processes in the value stream should get faster too. That said, unlike machine tools, people don’t come with handy rheostat dials so that we can speed them up at will. Trying to speed up physical work can lead to injuries; trying to speed up mental work can lead to mistakes. This is where Industry 4.0 comes into the picture: Remember that old saw about working smarter, not harder? That is exactly what digitalization of processes aims to achieve.

One excellent example of how communications technology – the backbone of Industry 4.0 – can speed up people processes is job scheduling. When it comes to planning machine utilization, many manufacturers use some variation on this fairly simple process: Someone from the front office of the business looks through the various jobs that need to go through the factory and puts them in order of importance. The act of ordering the jobs often comes down to a stack of papers: Shop floor travelers for each job are printed out, and the papers themselves are placed in the order that the factory should run them. There are some obvious drawbacks to this. For one, someone must manually print out orders and then sequence them. The sequenced paperwork must be delivered to the shop floor (go for a walk, anyone?). Changing the sequence means digging through stacks of paper to find the job you want to move: If that is controlled from the front office, it means another walking trip to the factory floor. On the off chance that the carefully ordered stack of job travelers gets disordered, someone who knows the job schedule must sort the papers out to set up the sequence again.

None of these tasks need to work this way though, because software tools exist to simplify scheduling. Instead of printing job travelers, job documentation becomes electronic. This requires an access point on the factory floor (PC or smart device), but it means that now our scheduler in the front office can manage the sequence of jobs without printing, sorting, or walking anywhere. And since there are no stacks of paper to get dropped (or have coffee spilled on them), the schedule is safe from accidents. When job priorities shift, the production schedule can shift too with the click of a mouse button, and the new sequence of work gets transmitted instantly to the people who need it on the shop floor. Even better, CAM software systems for driving CNC machinery can now include the ability to push production plans directly to a machine control from a networked PC. Instead of requiring the operator to manage the schedule, the operator can focus on his most important function: keeping the equipment running.

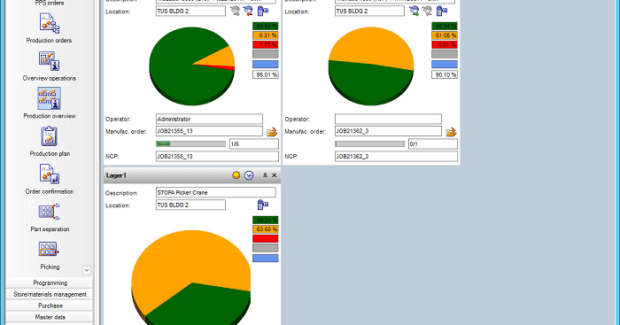

The other side of this coin is production status. If the job schedule determines how production should look on any given day, reality tends to be another story. There are so many reasons why our plan for the day and our reality on the factory floor can become out of sync – it can end up becoming a fact of life in many shops that the two just don’t match up. A team member in the front office wanting to know where production stands at the current moment will have to make that walk to the factory floor and see with their own eyes what is happening, along with maybe asking the factory floor team questions (and interrupting their work in the process). Communications technology can tackle this challenge. Software resident on a company server can communicate with software resident on machine controllers so that the production status of the machine can be monitored in real-time. Instead of going to the lasers to see what they are cutting, the software provides a clear view of the situation in the factory. Instead of going to an Excel spreadsheet and manipulating data to study your throughput and uptime, you can get graphical reports generated by the monitoring system.

If all of this sounds futuristic, it’s not: Manufacturing technology companies are offering these solutions today. Not just order and capacity management . . . software systems now can offer the capability to manage raw material inventory interactively. Did your sales team just bring in a big order for cutting? Instead of depending on the salesperson to go and talk to the buyer about material logistics, software systems can rapidly nest the required geometry, determine the quantity of material required, and generate a purchase order for the sheet stock for your buyer to approve. Tooling and consumables can also be managed interactively through systems similar to this. This saves time on the shop floor and the front office: Operators don’t have to worry about managing the inventory of consumables or (perish the thought!) having a machine stop running because of a missing nozzle, and controllers can manage and track the cost of consumables instantly.

These are just a few common examples. Much of the nitty-gritty of Industry 4.0 is about applying the newest available tools to truly age-old challenges: How do groups of people organize and coordinate their efforts to get the most done with the least time and energy? How can we tweak the setup to make it run just a tiny bit smoother? Anytime you must “go and see” something that could be transmitted electronically, that’s an opportunity to connect. Anytime you read data from one place and copy or send it to another, that’s an opportunity to automate. One of the great things about digitalization is that if you are just starting out, it’s pretty easy to take small steps. For example, start with an automatic quoting tool for your sales team that reads customer requirements (like CAD files) directly, instead of salespeople using spreadsheets and calculators to figure out pricing. From there, connect your quoting tool to your scheduling system or ERP so you can track and schedule your orders in real-time, then connect that system to your raw material inventory.

Opportunities to connect and automate are everywhere in any business: Looking for ways to improve the connections between your processes with technology is one way Industry 4.0 can have a positive impact on your workplace.