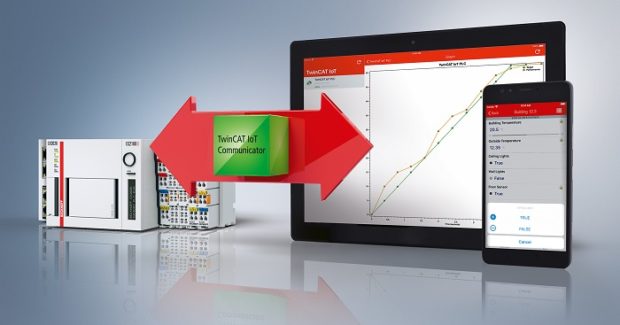

Secure Transfer of Process Data to Mobile Devices

TwinCAT IoT Communicator software and the IoT Communicator App for tablets and smartphones from Beckhoff Automation uses advanced encryption and protocol for easy mobile device integration and high-level communication security.

Posted: May 30, 2019

The TwinCAT IoT Communicator from Beckhoff Automation LLC (Savage, MN) makes it easy for PLCs to communicate with mobile devices by connecting the PC-based TwinCAT controller directly and securely to a messaging service through TLS encryption. For smartphone and tablet users, the associated IoT Communicator App ensures that process data can be represented on all mobile devices in a clear overview. Alarms are sent to the device as push messages. The TwinCAT 3 IoT Communicator exchanges data using a publish/subscribe mechanism. Since no special firewall settings are needed, integration into an existing IT network is easy. Information is exchanged via a message broker that uses the standardized MQTT protocol and acts as a central messaging service in a cloud or local network. A high level of communication security is guaranteed by proven TLS encryption (up to version 1.2).

Transmitted process data can be displayed on mobile devices using the IoT Communicator App, which is available for both Android and iOS operating systems. It also incorporates an integrated QR code scanner to facilitate entry of access data for communication between the broker and individual users. The TwinCAT IoT Communicator simplifies the transmission of push messages in industrial applications and offers a number of advantages over conventional email and SMS messages by visualizing live data, variables and status values – making it an ideal addition to the related TwinCAT IoT and TwinCAT Analytics software systems.

Beckhoff Automation also provides a machine learning (ML) system that is seamlessly integrated into their TwinCAT 3 software. Building on established standards, TwinCAT 3 Machine Learning offers ML applications the same advantages of system openness familiar from PC-based control technology. In addition, this TwinCAT system supports real-time ML, allowing it to simultaneously handle demanding tasks like motion control. These capabilities provide machine builders and manufacturers with an optimum foundation to enhance machine performance, for example, through predictive maintenance, process self-optimization and autonomous detection of process anomalies. With machine learning, controls engineers no longer have to follow the traditional engineering route of designing solutions for specific tasks and turning those solutions into algorithms. Instead, the automation controller can learn the desired algorithms from exemplary process data. With this alternative approach, powerful ML models can be trained and then used to deliver superior, higher performing systems.

In automation technology, this opens up new possibilities in many areas, including predictive maintenance and process control, anomaly detection, collaborative robotics (cobots), automated quality control and machine optimization. The models to be learned are trained in an ML framework, such as MATLAB® or TensorFlow, and then imported into the TwinCAT runtime via the Open Neural Network Exchange Format (ONNX), a standardized data exchange format used to describe trained models. The TwinCAT runtime incorporates the following new functions for this purpose:

- TwinCAT 3 Machine Learning Inference Engine for classic ML algorithms, such as support vector machine (SVM) and principal component analysis (PCA).

- TwinCAT 3 Neural Network Inference Engine for deep learning and neural networks, such as multilayer perceptrons (MLPs) and convolutional neural networks (CNNs).

Inference, i.e. the execution of a trained ML model, can be performed directly in real-time with a TwinCAT TcCOM object. With smaller networks, system response times of less than 100 µs (corresponding to a TwinCAT cycle time of 50 µs) are supported. Models can be called via PLC, C/C++ TcCOM interfaces or a cyclical task. Through seamless integration with the control technology, the multi-core support provided by TwinCAT 3 is also available for ML applications. This means, for instance, that different task contexts can access a particular TwinCAT 3 Inference Engine without restricting each other. All fieldbus interfaces and data available in TwinCAT remain fully accessible as well. This allows ML solutions to use immense amounts of data, for example, for complex sensor data fusion (data merging), and it also means that real-time interfaces to actuators are available to enable, among other things, optimal controller performance.

To further increase connectivity options in ultra-compact PC control hardware, Beckhoff Automation introduced the high-performance C6032 Industrial PC (IPC) device with dimensions of only 129 mm x 133 mm x 104 mm in a modular design that adds two slots for PCIe Compact modules to the C6030 single-board IPC, which is comparable in terms of computing power to accommodate modular interfaces and functional extensions. By using compact PCIe modules, the C6032 can optimally adapt to the unique requirements of individual applications. Equipped with powerful Intel® Core™ i-processors of the 6th and 7th generation – up to the Core™ i7 with four 3.6 GHz cores – the C6032 is ideal to support extensive multi-axis motion control, complex HMI applications, extremely short cycle times and handling of large data volumes. Its compact motherboard and die-cast zinc and robust aluminum housing provide high standards of industrial-grade assembly, high reliability and a premium look and feel. With vertical or horizontal mounting at the rear of the enclosure, its flexible installation options provide totally free orientation of the connection area.

The two PCIe compact module slots enable flexible expansion of the connection area on the front of the device. The first available PCIe modules are the 2 x Gbit Ethernet, 2 x USB 3.0, 2 x RS232, and the 1 x CP-Link 4 (for connection to Beckhoff industrial displays). The use of an extremely durable, speed-monitored and controlled fan makes this device suitable for an operating temperature range of up to 55 deg C. Available options include Windows 7 or Windows 10 operating systems, as well as a second M.2 SSD in RAID configuration. There is storage capacity of 40 GB M.2 SSD, 3D flash even in the basic configuration. This Microsoft Azure™-certified device is ideal to meet current requirements in machine building, such as increasing modularity, reduced space requirements in control cabinets and increased computing power at an affordable price point. This makes the C6032 suitable for use in a broad range of application scenarios, including distributed architectures and current Internet of Things (IoT) or Industry 4.0 concepts, with exact computing power that is flexibly scalable to suit nearly all medium to high-end machine performance levels.

In Industry 4.0 and Big Data applications, machine data acquisition via OPC UA and analytics tools are becoming increasingly important. This information must be presented in a clear and efficient manner, and the machine control system must also cover a wide range of other smart components. Beckhoff Automation offers greater integration of OPC UA communication technology into their TwinCAT Scope software, providing optimum support for integrated data acquisition across heterogeneous system environments. A standardized OPC UA communication channel enables this charting tool to analyze data from diverse sources, such as TwinCAT controllers and third-party components. TwinCAT 3 Scope consists of Scope View for the graphical display of signal curves and Scope Server for the actual data logging.

The Scope Server can be installed on a target device for autonomous logging (without the View component if desired) or on the corresponding engineering system together with Scope View for remote logging – which means no additional software has to be installed on the target device, no updates to TwinCAT controllers are required, and devices without TwinCAT software do not require modification to display their data graphically in Scope View. For logging measured signals, the Scope Server not only features a TwinCAT-specific ADS channel, it also offers support for another standardized communication channel in the form of an OPC UA client. The widespread use of OPC UA in automation technology enables TwinCAT Scope to acquire and display measured data in a vendor-independent way. With OPC UA, this can be achieved reliably and securely, especially if certificates are used.

The TwinCAT Target Browser ̶ which is used to manage connected data sources in TwinCAT Engineering ̶ has been expanded with OPC UA support. It enables browsing in the namespaces of connected OPC UA servers to select the desired variables for logging by the Scope Server with configuration options for certificate-protected access. A TwinCAT 3 Engineering installation always includes a Scope View tool and a local Scope Server. Both software components are included free of charge in the basic version, which enables testing of the OPC UA communication. With a rich set of features including multi-core support, triggers, chart synchronization and numerous zoom functions, this tried and tested charting tool is now perfectly suited for an even larger group of users and even more diverse application scenarios with these newest communication enhancements.

For more information, look at other advances in IIoT and also subscribe to F&M.

Beckhoff Automation LLC, 13130 Dakota Avenue, Savage, MN 55378, 952-890-0000, Fax:952-890-2888, [email protected], www.beckhoffautomation.com.