Online Equipment Monitoring Drives Productivity Improvements

The CoroPlus MachiningInsights digital system from Sandvik Coromant collects data directly from a connected machine tool and input from operators, making it possible to visualize machine and tool utilization levels online through a web browser and collaborate to make improvements within the factory.

Posted: May 30, 2019

For many shops, knowing when a machine has stopped – and identifying the underlying reason for the stoppage – can be a major challenge. Digital systems are creating new possibilities to overcome this issue. Using digital systems to monitor equipment utilization makes factories far more efficient and profitable than they could be otherwise. For shops looking for an easily attainable step to reduce waste in production and make a smooth transition into a digital way of working, CoroPlus® MachiningInsights from Sandvik Coromant (Fair Lawn, NJ) is more than a monitoring system: Developed in recognition that a machine standing idle is not making money, this digital solution gathers data, calls attention to issues and provides the insights required to take action. Replacing traditional methods of manual tracking, manual data aggregation and manual time studies, collecting data directly from a connected machine tool and from operators makes it possible to visualize the machine and even tool utilization levels to create improvements within the factory.

By using CoroPlus MachiningInsights to analyze equipment utilization and act to optimize production processes, machine shops can make substantial efficiency gains. Their analysis is facilitated by digital connectivity and, by adding the capability of operator input into the system, creates more opportunities for increased collaboration and greater efficiency by combining data from the operator with data from the machine. Transparency is ensured through the visualization being carried out online and being accessible by a web browser. This means there is no need for a complicated IT project to get up and running. This rapid and simple method of incorporating digital manufacturing intelligence into a shop drives improvements in operations. That’s not all. Sandvik Coromant customers can now customize a cutting tool online without having to speak to a sales representative, substantially reducing the time to place an order for customized tooling solutions – which, in turn, reduces overall tool delivery time.

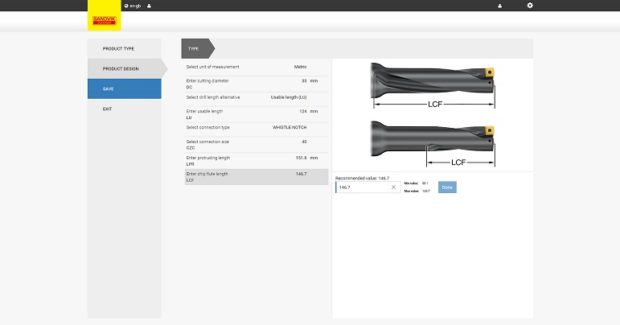

Many manufacturers benefit from using cutting tools that are not available “off-the-shelf.” The most common example is when a specific, non-standard hole diameter is specified. Producing such a feature typically entails an initial drilling operation, followed by boring to the required size. But by applying a small modification to an existing off-the-shelf drill, the manufacturer can create the hole according to specification using just one drill. Previously, the process of quoting and ordering customized solutions required either downloading, completing and sending in a physical form, or consulting with a sales representative. Now, however, any registered Sandvik Coromant web user can log in and start using this newly developed feature in their browser for free. The user can click through a few guided steps and customize a standard cutting tool to match specific requirements. In the final step of the process, the user simply places the order.

“The world of manufacturing is changing, with an increasing need for greater flexibility in tooling,” said Brian Davis, the manager of global sales processes at Sandvik Coromant. “This trend also impacts cutting tool suppliers. Offering customized cutting tools demands the development of advanced processes, and making this customization option available to all of our customers is a bold move, but one we know offers multiple benefits.” Clearly, a faster tool customization process translates directly into faster tool delivery, all without losing time in conversation with sales representatives. Further advantages include the availability of a larger number of tools on the web (beyond standard tools), as well as a new opportunity to review any customized tools sent via sales representatives. In addition to drills, this online service applies to parting and grooving, milling and tooling systems as well.

For more information, take a closer look at other advances in cutting tools and also subscribe to F&M.

Sandvik Coromant US, 1702 Nevins Road, Fair Lawn, NJ 07410-0428, 201-794-5000, Fax: 1-201-794-5157, www.sandvik.coromant.com.