How to Effectively Manage Multi-Operation Assemblies

These difficult jobs are increasingly more customized, with shorter lead times and tougher pricing pressure. Any change in the process or machinery can cause huge setbacks in production and eat into your profits. What is the answer to managing this type of work?

Posted: May 28, 2019

In today’s competitive environment, many shops struggle with the ability to successfully manage and effectively control jobs that are made up of multi-operation tube assemblies and are increasingly more customized, with shorter lead times and tougher pricing pressure. Each of these jobs requires a detailed process workflow and the right machinery with the correct tools to help overcome these challenges. Any change in the process or machinery can cause huge setbacks in production and eat into profits. What is the answer to managing this type of work? Having the right “set of tools” inside your “toolbox” can set your shop apart from your competitors, ensure success throughout production – and increase your profit margins on those difficult jobs.

INSIDE THE TOOLBOX

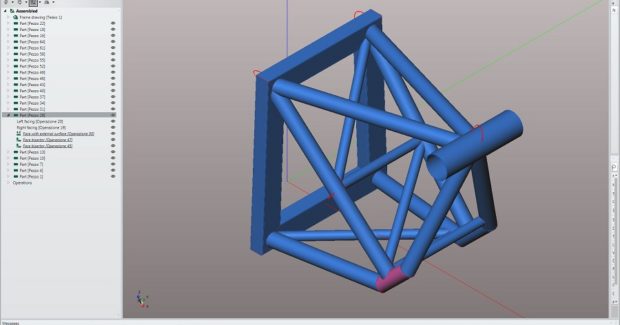

What is this toolbox? An integrated, secure programming and management software suite such as our BLMelements that groups programming, simulation, management and production control tools together to provide you with the ability to see the end part as a whole – without needing to program each single job separately, regardless of whether the operation involves laser cutting, bending or end-forming – a practical benefit that saves lots of time and money where multiple machine operations are needed for production. For example, starting from a three-dimensional model of an assembly, you can use these tools to recognize and examine the various individual parts, analyze the jobs required to process them, then manage the production automatically:

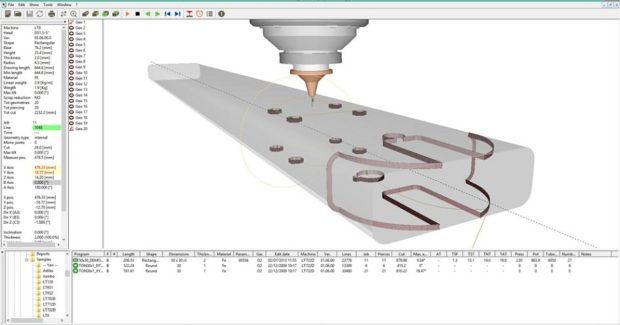

- Artube 3 is an extremely powerful Lasertube CAD/CAM programming application with many add-on modules that make it one of the most advanced laser design systems offered. It can process all CAD file formats: STEP, IGES, XT and even IFC. Part models created with other CAD programs and imported in this application are transformed into native models. After importing a part CAD model, the user has access to advanced libraries that include fitting and cut-bend options. These features can be applied to the model with a click of a mouse, simplifying complex operations that typically require a great deal of time and expertise to put together. The module for importing 3D models is just as effective. The Assembler module allows a user to import complex tubular structures, not just individual parts, to make managing assemblies extremely easy. Multi-technology models, including bent tubes, can also be imported. Bending operations are automatically recognized and managed by creating the part program to be sent to the bending system. This capability simplifies communication in a production cell. The CAM module converts the 3D model to CNC code and writes the part program directly without any manual operation.

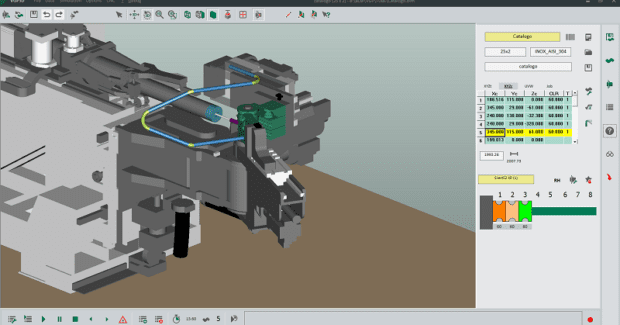

- VGP3D is an extremely simple and versatile bending programming and management system. The tube design is displayed in 3D mode gradually as the operator enters the data of each bend with a very simple and intuitive sequence of operations. At the end of the programming operation, a 3D graphic simulator shows the real processing of the part on the selected bending system and highlights any possible collisions that could affect production and part quality. Having this ability to import 3D models of the bent tubes and link to Artube to receive part programs prepared in advance makes this software convenient and easy to use.

- PartViewer is a powerful application for simulating the Lasertube system part programs that enables a user to manage archived part programs and display each one graphically in 3D. Part programs can be filtered by section shape or size, material type or thickness, machine type, customer, etc. and retrieved to accurately analyze the time and costs of the job. This greatly simplifies the effort of costing jobs and developing quotes for new work, and allows process parameters to be modified to immediately see the impact to system productivity.

- The Composer application is used to manage part families with parts that have common features but differ in relative dimensions and/or feature locations. The detailed models of the family are saved and can be easily called up and sent into production, with parameter information related to the variable dimensions only. An external ERP that can be easily interfaced with the Composer can be used for selecting the part family and defining measurements.

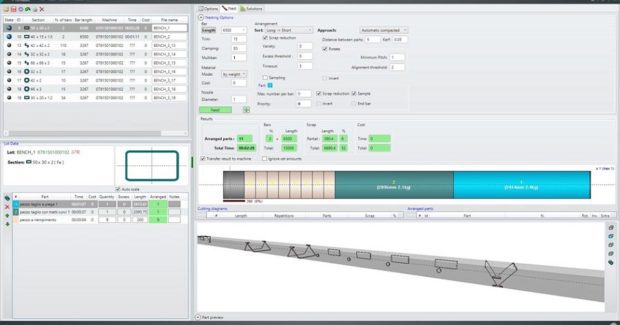

- Production management can be accomplished in the office using ProTube. Efficiencies can be gained by organizing machine programs into combined work orders and sending the jobs to each system connected to the network. Each batch contains the job settings that will optimize quality and execution times. Machines that are networked send information – such as operating state, event history, job progress, and other machine-related conditions – back to Protube for optimal management of current production. With the integrated chat function, a production manager can send messages to the machine operators for timely communication. All processed batches, work orders and jobs are filed in the centralized server and can be reopened at any time to be launched for production or updated.

The benefits of owning machinery with advanced software capabilities aid your shop’s ability to cost jobs accurately, manage production to reduce lead times, and increase capacity with efficiency gains. Utilizing a collective programming and management software platform to gather, transfer, and analyze real-time operations data allows production managers and operators to troubleshoot quickly and reduce downtime. The workflow of multi-operation assemblies is smoother throughout the production process, allowing your shop to focus on profitability and growing your business.