End-To-End Digitalization for the Machine Tool Business

In both the construction and utilization of machine tools, Siemens is laying the foundation for digital penetration and restructuring of complete value chains that will boost the growth and profitability of both machine builders and users alike in shops of all sizes.

Posted: May 29, 2019

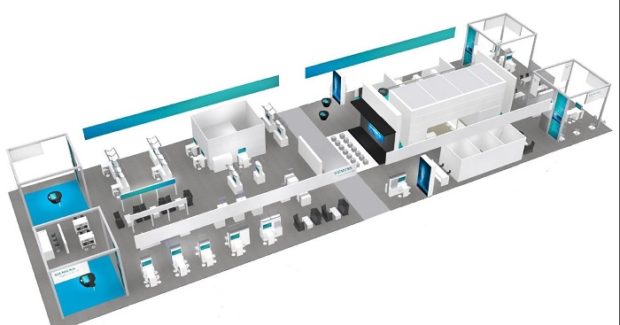

The integrated, end-to-end “Digitalization in Machine Tool Manufacturing” offered by Siemens Industry, Inc. (Elk Grove Village, IL) provides ways for CNC machine users and builders alike to significantly boost their production flexibility and efficiency, drastically reduce their engineering input and time-to-market, and consolidate and expand their competitive standing in the global marketplace by digitalizing their operations. “Digitalization is set to fundamentally transform and advance the machine tool business,” explained Dr. Wolfgang Heuring, the chief executive officer of the Siemens Motion Control Business Unit. “Linking the digital and real worlds opens new possibilities to boost productivity and develop totally different business models for both machine builders and users, for small and medium-sized shops, for the big players in the industry. Digitalization is the main driver of growth and profitability in this industry, so we are laying the foundation for digital penetration and restructuring of complete value chains in this business, in both the construction and utilization of machine tools.”

The Digital Enterprise Suite from Siemens includes software-based systems and automation components that cover every conceivable requirement arising along the industrial value chain. Its backbone is formed by the Teamcenter digital lifecycle management system. The digitalization portfolio for machine tool builders ranges from the machine concept and engineering through to commissioning and servicing. For machine operators, digitalization systems cover their entire value chain, from product engineering and production planning to actual production and digital services using Manufacturing Operations Management (MOM), Simatic IT, Sinumerik CNC and Simatic S7 PLC systems.

Siemens links CNC machine tools across the world by using the Manage MyMachines application to connect them to the open cloud-based IoT operating system MindSphere. This allows machine operators to have a cloud-based overview of important machine data and the current operating status of their machines. The resulting transparency allows users the chance to respond and optimize their production accordingly. They can use Sinumerik Edge – a robust, high performance hardware and software system for machine-level application (edge computing) – to collect and analyze process data practically in real-time with the machining process. Decoupling the data processing tasks and process control ensures the necessary degree of process security, for which customized edge apps are available for functions such as monitoring and optimization. Machine tool builders and service providers can also integrate their own Edge apps into this open platform.

For more information, take a closer look at the changing supply chain and also subscribe to F&M.

Siemens Industry, Inc., Drive Technologies – Motion Control, 390 Kent Avenue, Elk Grove Village, IL 60007, 847-640-1595, Fax: 847-437-0784, www.usa.siemens.com/cnc.