Digital Metrology Marks Milestone

They celebrate 20 years in the measurement software business.

Posted: May 7, 2019

Digital Metrology Solutions (Columbus, IN) marks their 20th year of service in May, 2019. Founded in 1999 by Dr. Mark Malburg, they have aided hundreds of companies in solving product and process development issues by developing and applying advanced metrology technologies. “We realized early on people don’t want to measure . . . they want to understand. It isn’t the measurement that matters, it’s what you are able to do with the data,” said Dr. Malburg. “We have made it our mission to provide tools to help users communicate and effectively use measurement data for understanding and improving component performance.”

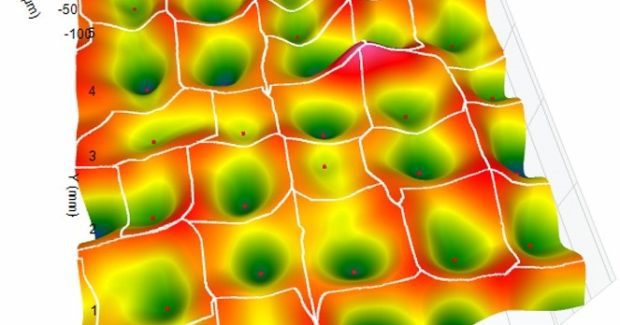

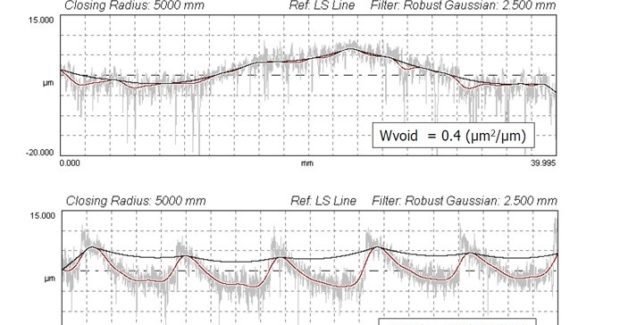

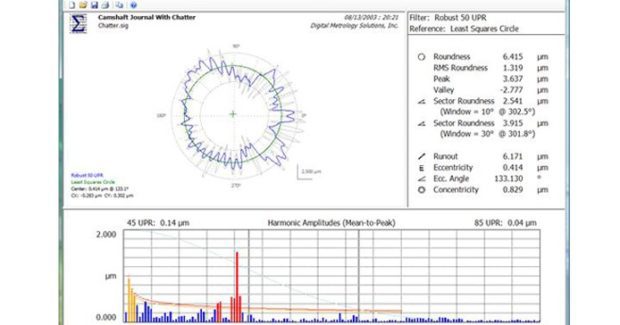

The company was originally formed to develop software for custom metrology applications, such as measuring unusual profile geometries and/or features of interest. In recent years they have collaborated with instrument manufacturers around the world to develop measuring systems and to embed software in custom and off-the-shelf metrology systems. The success of their earlier custom work eventually led to several widely successful, general-purpose software packages, including OmniSurf for 2D surface profile analysis, OmniRound for roundness and harmonic analysis and, more recently, OmniSurf3D for 3D surface texture analysis.

“When we entered the metrology market, most surface and geometry analysis was performed on the instrument, using the instrument’s own proprietary software. We saw a need for a simple-to-use software that people outside of the lab could use. The best understanding of a shape comes from interacting with the shape, not simply reporting a number,” Dr. Malburg continued. “Through the years I’ve heard many customers say that the engineer’s ability to interact with the data, in their offices, has led to major breakthroughs in product understanding and development. We are proud to be able to say that we are at the core of many modern measurement systems in surface and form metrology.”