Automatic Data Analysis Increases Shop Floor Efficiency and Reduces Downtime

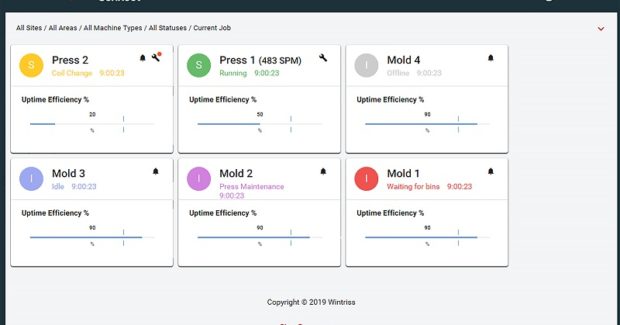

ShopFloorConnect 6.0 OEE and Shop Floor Data Collection software from Wintriss Controls gathers production data from every machine in the factory, displays the Key Performance Indicators in real-time and produces detailed analytics, including comprehensive OEE reports in a variety of formats.

Posted: May 30, 2019

Wintriss Controls Group (Acton, MA) introduces ShopFloorConnect® 6.0 OEE and Shop Floor Data Collection software that gathers production data from every machine in the factory, displays the Key Performance Indicators (KPIs) in real-time and produces detailed analytics, including comprehensive OEE (overall equipment effectiveness) reports in a variety of formats. Using superior calculations that accurately report OEE for even the most complex manufacturing environments, this production tracking software provides machine downtime and manufacturing efficiency reports via a web browser and email, and integrates with existing systems. It can significantly increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks. “Automatically collecting important efficiency and downtime machine data results in on-time, accurate reporting while removing subjectivity,” said Keith Magnant, the ShopFloorConnect sales manager. “This software provides an extremely easy-to-use, efficient data collection system that can reduce machine downtime by up to 70 percent.” This scalable and flexible production monitoring system is compatible with all ERP software, making it well-suited for discrete manufacturing and metal fabrication shops.

For more information, look at other advances in machine connectivity and also subscribe to F&M.

Wintriss Controls Group, 100 Discovery Way, Unit 110, Acton MA 01720, 978-268-2700, Fax: 978-263-2048, www.wintriss.com.