Turning the Corner on Demanding Precision Jobs

Methods Machine Tools offers the Nakamura-Tome SC-300IIMYB multitasking turning center for machining difficult, high-hardness materials with extremely high accuracy, the Tornos Multi-Swiss 8×26 automatic lathe and the Tornos SwissNano for very high precision machining of complex small parts.

Posted: April 23, 2019

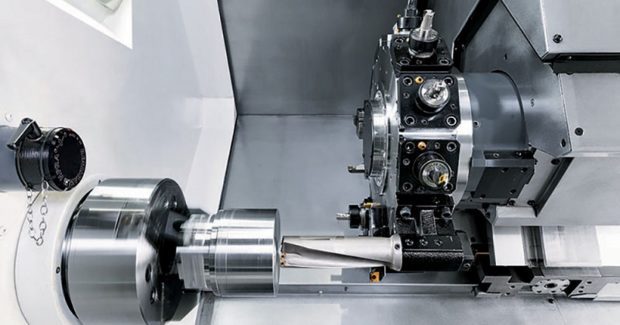

For maximum versatility and productivity, the high precision Nakamura-Tome SC-300IIMYB multitasking turning center from Methods Machine Tools, Inc. (Sudbury, MA) has an extremely rugged machine structure with a massive 45 deg slant bed and box-way slides on all axes and a firm 12-station turret that provide the rigidity required to machine difficult, high-hardness materials with extremely high accuracy. This turning center uses a FANUC CNC control and servo drives and features a 3,500 rpm main spindle with a 3.5 in (89 mm) bar capacity and a high torque, wide range, 30 hp main spindle motor for powerful cuts. A 10 hp, 6,000 rpm milling turret with a large 4.7 in (120 mm) Y-axis travel provides increased capacity and enables fast machining with a cutting depth of .35 in (9 mm).

Methods also offers the Tornos Multi-Swiss 8×26 automatic lathe with 8 spindles and 8 slides for main operations. This lathe features a simple, sequential-operation programming format as well as a streamlined, compact footprint that includes mobile spindles with Z axes, barrel indexing using torque motor technology, and a container housing all of the peripherals required for machine operation. This machine marks a departure from conventional multi-spindle machines, providing the link between multi-spindle and single-spindle turning machines. Its on-board technology can deliver cycle times equal to those of cam-operated multi-spindle turning machines.

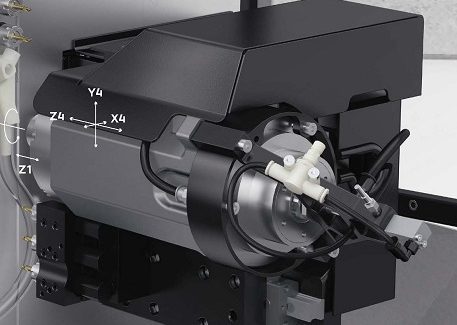

Methods offers the Tornos SwissNano for the most demanding, very high precision machining specifications on small workpieces, including the most exacting watchmaking requirements, as well as gear hobbing, polygon milling, thread milling and internal thread-whirling. With a symmetrical cast iron frame, its rigidity is optimized in order to guarantee flawless finishes and extended life on cutting tools. Repeatability is very high and the precision of the machine is consistent throughout production. Kinematics with six linear axes and two independent tool systems enable turning and drilling, cutting/deburring and roughing/finishing that can produce the majority of turned parts of a watch movement measuring up to 4 mm; from the simplest to the most complex pieces, all with excellent finishes. With unrivaled thermal stability thanks to a short thermal loop and comprehensive and active machine thermal management, the capability of the SwissNano extends beyond horological applications to any type of part requiring extreme quality and precision.

Methods Machine Tools, Inc., 65 Union Avenue, Sudbury, MA 01776, 978-443-5388, Fax: 978-440-9405, www.methodsmachine.com.