The Jig is Up: Flexible Part Positioning

Whether welding or handling, the flexibility of a six-axis robot arm is tough to beat. A single workcell with multiple robots can complete several processes with great reliability for the consistency needed to maintain 24/7 operations in an industrial climate that lacks skilled workers.

Posted: April 12, 2019

As a fundamental component of most traditional welding applications, part positioners have been used for decades to provide the welder with a way to hold and turn the parts being welded together. Although positioners come in many different designs, each serves the same primary purpose: hold the part in a predictable and repeatable position to improve part quality. Positioners vary in style and size, and each is uniquely designed to fulfill unique manufacturing requirements. While typical positioners have one or two axes to rotate a part and sometimes tilt it, others are made to lift and rotate huge parts. All positioners use some sort of tooling to hold the assembly together as an operator loads new components and unloads the welded assembly – a process that can impact cycle time depending on the complexities of the part and capabilities of the operator.

Due to their wide use, complete positioners and tooling jigs have carried over from manual welders to robotic automation. From basic flat tables to complex multi-axis servo motor positioners, modern-day servo-driven positioners offer better control and accuracy than electric, hydraulic and pneumatic positioners, easily meeting a wide variety of process needs. Servo-driven positioners can be controlled from the robot controller and programmed to move in coordinated motion with a single robot or multi-robot application, as well as with other servo motors. This allows access to multiple sides of a part and enables the welding of complex parts.

A DIFFERENT APPROACH

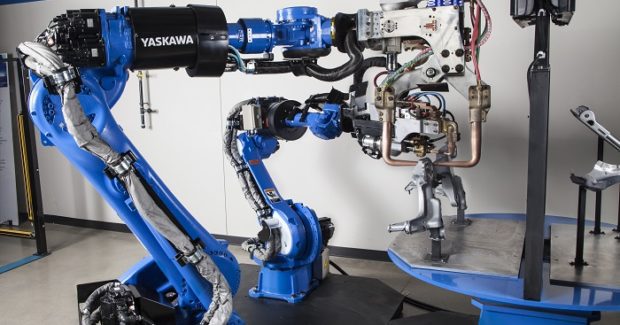

While the use of robotic servo-driven positioners is quite effective and integrated into most modern robotic welding workcells, tooling changeovers can sometimes be difficult and slow, and the tooling itself can be costly. For this reason, a different approach to consider for the welding of parts – especially weldments that are large, boxy or tubular – is to replace the positioner and tooling jig with a robotic arm (or two). This is commonly known as “jigless” robotic welding, where the robot holds and positions a part for processing by other robots, or two robots handle a single part. Similar to human movement, robots have the ability to rotate, bend and move in an arc-like fashion. This enables the use of more simplified tooling as the robot grips the parts and it provides the six degrees of freedom needed to manipulate the part in nearly any orientation or direction, while handling a wide array of workpieces in both high-volume and low-volume environments.

ADVANTAGES VS. DISADVANTAGES

The increased demand for more flexible part positioning has caused shops of all sizes in various industries to thoroughly consider the pros and cons of going jigless:

Advantages

While the cost of a robotic arm is approximately the same as a tilt-turn positioner and both can be accurately controlled to a fraction of a millimeter by a common pendant and controller, common tilt-turn positioners only provide two degrees of freedom. With a six-axis robot that is capable of lifting, lowering, twisting and turning in any direction, a very complex part can be turned as many times as an application requires. This ultimately helps to rotate and tilt parts in a faster, safer and more consistent manner – not to mention a robot’s footprint is often smaller, saving valuable floor space in the shop for future expansion. Similarly, the combination of handling robots with welding robots is more conducive to automated loading and unloading. While some manufacturers choose to do this with the same robot arm, it is more realistic to implement the use of a second robot for the task.

When a second handling arm is added to a welding application, it reduces human interaction by bringing parts to the weldment and holding them in place while the welding robot tacks before full weld. This alleviates human workers from doing the dull and dangerous tasks of lifting and potentially reduces cycle time to optimize return on investment. These advantages also aid in automating a low-volume, high-mix job shop. By eliminating expensive and frequent tooling changeovers, tooling on a handling robot may be adapted quickly for a number of similar parts. This can also be achieved by using two handling robots: one that holds the base part and another that places and holds the part to be added and welded.

Disadvantages

On the flip side, a common positioner is quite robust, supporting payloads from 150 kg (331 lb) to 2,000 kg (4,409 lb). This can make the idea of using a robot for a jigless application a tough sell, especially if the robot arm only supports between 10 kg (22 lb) and 250 kg (551 lb). Weldments requiring robots with greater payload capacity for large parts will most likely add cost to the initial capital expenditure, causing manufacturers to think twice before implementation. Unlike robots, servo-driven positioners have an infinite axes range that never requires “unwinding” if a part needs to be turned many times. Taking this into consideration is highly suggested when programming a part on a jigless system, because the robot wrist will likely be limited to a specific range (usually ±360 deg, but only as high as 550 deg or 720 deg in some models).

Lastly, most servo positioners, like turntables and ferris wheels, have a side “A” and side “B” where one is being processed while the other is being loaded and unloaded to reduce overall cycle time. A jigless system would require a second robot to possess this attribute, which may negate either cost savings or cycle time for more complex parts that take longer to assemble during tooling load.

FINAL CONSIDERATIONS

A welding robot can only weld what it can reach. To make that happen, manufacturers need to take a look at the big picture. From implementation costs to return on investment and everything in between, all key factors must be weighed, including prioritizing goals for flexibility, cycle time, part compatibility and future part considerations. While traditional welding systems may offer tooling to properly position a part, configuring the right positioner to accommodate reach constraints can add up quickly. In cases like this, the benefits of jigless welding are attractive to many manufacturers. More and more shops are moving to jigless-style applications to meet quality standards and time-to-market goals set by their customers.

Whether it is welding or handling, the flexibility provided by a six-axis robot arm is tough to beat. The potential to complete multiple processes in a single workcell with multiple robots is strong and the reliability factor is even greater, providing the consistency needed to maintain 24/7 operations in an industrial climate that is lacking skilled workers.