Setting A Big Track Record

To construct the unique architectural look of a new track and field arena using curved piping structures, this specialist in complex steel fabrication invested in one of the only standalone automated pipe processing plasma cutting machines in the world that can process 60 ft long pipes – and it paid off big time.

Posted: April 5, 2019

Specializing in complex steel fabrication for more than 70 years, Fought & Company (Tigard, OR) is used to going big, routinely building some of the largest structures in the western U.S., including stadiums, airports, schools, hospitals, malls, and bridges. They were recently given the opportunity to bid for a project they found intriguing: A new world-class track and field center. “The track and field arena is a one of a kind project,” explains Wayne Searle, the chief executive officer of the company. It has components that aren’t typically part of a regular steel project. Big plate columns come up that we have to manufacture in pieces and it has pipes that sit on the back side called a diagrid system.”

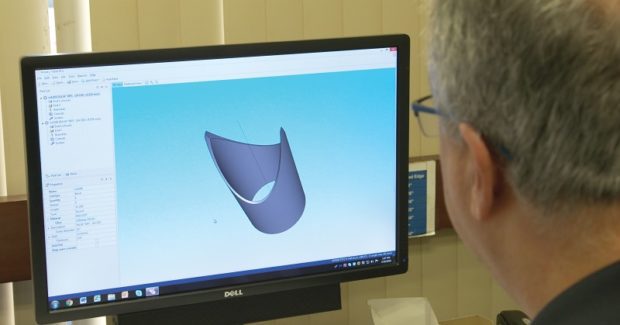

Because the stadium is designed to have a unique architectural look with curved piping structures, Searle knew that to submit a competitive bid, he would need new equipment, so he approached Machitech Automation (Saint-Marc-des-Carrières, QC), a manufacturer of CNC cutting systems. After learning of the project requirements to precision cut complex shapes in 30 in diameter pipe, Machitech recommended a PipeCut™ machine, one of the only standalone automated pipe processing plasma cutting machines in the world that can process 60 ft long pipes. This machine comes with a 5-axis bevel head and several system components from Hypertherm Inc. (Hanover, NH), including an XPR300 plasma cutter with X-Definition Plasma technology, an EDGE Pro CNC, ProNest nesting software and Rotary Tube Pro software. “This new plasma provides finer cut quality than other systems on the market,” notes Sean Lawlor, a Machitech product specialist. “Hole and edge quality are closer to laser than ever before, at a much more affordable price point.”

These capabilities are very attractive in the highly competitive steel fabrication market, where everyone is busy and pricing is a challenge – forcing Fought & Company to continuously look at how they can do things quicker, faster, and better than their competitors. This new cutting system has provided them with some versatility. “We can do the types of projects that we couldn’t do before,” says Searle. “And because of the speed and accuracy, we’re able to get work that we normally wouldn’t be able to get, so we have a higher market share. One of the things that I like most about this machine is that once the product has been cut, it’s done. We can take it and can go to work immediately – no more cleanup, no more grinding, knock a little slag off and go right to work. We save lots of time and money.”

https://youtu.be/Z9hJkME8WGc

Even adding bevels and holes are done properly with no clean-up required, and overall productivity is up an estimated 90 percent – a big savings for any industry, but especially steel construction, where one of the greatest challenges is having to repeat work over and over again. “The cut quality of the bevels and holes is actually very good, compared to cutting them by hand,” adds Carlos Paladini, the employee responsible for operating the system. “The machine actually does them exactly at the angle you need to have them, and they are extremely accurate and precise. Before getting the XPR, we cut the pipe by hand using a saw, or beveled it with a grinder. Not only did the process take us much longer, it was not as accurate.” The shop has to routinely cut what Searle calls a “fish mouth” and other shapes into the pipe. There isn’t a lot of room for error. “If it isn’t cut properly, we must cut, grind and hack things apart to fit up and make it right,” he says. “Now we cut it one time and create a fish mouth shape. We put it on there and go right to work.”

Now they take on more projects that couldn’t be done prior to the new system. “Before we had the plasma pipe cutter, we had to lay things out with a template,” he explains. “It was tedious and cumbersome. You’d manually mark a line then cut it, most likely with an oxy acetylene torch. What took 8 to 16 hours then can be done now in less than an hour. In some cases, it takes less than a minute.” Part of this speed advantage is achieved by the ProNest and Rotary Tube Pro software used with the system. Programmer Fred Butkovich says the new software is very user-friendly: “As far as plate cutting, the ProNest is simple to learn and use. As far as pipe cutting, this is our first software. We didn’t have any software for pipe cutting before this.”

Butkovich echoes Searle in explaining how the shop no longer needs to outsource: “We did a project not long ago with fish mouth cutting and we subbed that material out because we didn’t have the capability to do it. Now we don’t need to outsource. If somebody else has pipe to cut, we may be able to bring it in and do jobs for other people. We can also do slotting – putting holes in the pipe – which is something we pretty much had to lay that out manually before. Now we do it all on the machine.”

Fought & Company, 14255 SW 72nd Avenue, Tigard, Oregon 97224, 503-639-3141, www.foughtsteel.com.

Hypertherm Inc., PO Box 5010, Hanover, NH 03755-3124, 603-643-3441, www.hypertherm.com.