Rockford Systems Forms New Division

The Combustion Safety Division led by Robert Sanderson provides turnkey systems for thermal processes.

Posted: April 1, 2019

Under his leadership of the new Combustion Safety Division, they will expand their industrial safety portfolio into fuel and thermal safety fields.

Rockford Systems, LLC (Rockford, IL) is expanding their industrial safety solution portfolio to better meet the manufacturing safety needs of their customers. They have launched a new Combustion Safety Division (RSCS) that provides turnkey systems for organizations that use thermal processes in their operations. This expansion enables them to provide new and complimentary value-added safety systems and enables traditional safeguarding customers the ability to grow their industrial safety focus with a trusted and reliable partner.

The new division is led by Robert Sanderson, a registered professional engineer with over 25 years of industry experience, who has been appointed to the position of the director of business development. Prior to joining the company, he started his career as the primary thermal and applied process expert for a global corporation that built automotive and aerospace assembly plants. Subsequent to that, he continued as an industrial combustion and emissions technology specialist for a Fortune 100 company. Sanderson has assembled a world-class combustion safety team with capabilities covering the initial sale, through engineering and manufacturing, and concluding with installation, service and post-sale support. He is a prior member of the NFPA 86 Standards Committee and holds a Bachelor’s Degree in Mechanical Engineering from The University of Michigan. Under his leadership, this new division will expand their industrial safety portfolio into fuel and thermal safety fields.

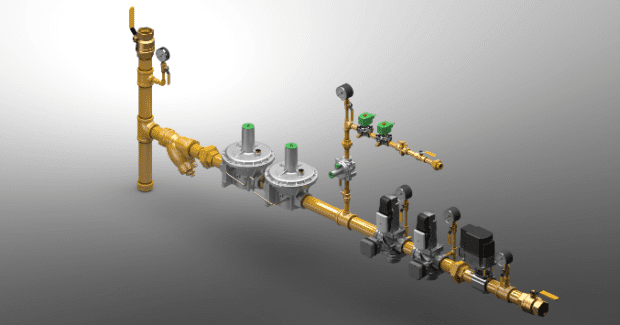

An important part of the new division’s value proposition is best-in-class delivery, which benefits customers by decreasing production downtime. To achieve delivery in days rather than weeks or months, they offer an array of standardized valve safety trains that are pre-engineered, modular, assembled from existing segments, and importable as 3D models for customers’ CAD systems. Their modular design eases installation, as does the prewired option. Standard valve safety trains are stocked and available in multiple sizes with capacities up to 7,500 standard cubic feet per hour (SCFH) and pre-designed units with capacities up to 22,500 SCFH. Customized layouts for any capacity, fuel, footprint or environment are also available.

Valve safety trains control the flow of gases for industrial equipment such as furnaces, ovens, dryers and boilers, making them a crucial component in assuring operational safety and energy efficiency. Owing to the presence of hazardous vapors and gases, a poorly designed or inadequately maintained system can lead to explosions, fires, asphyxia and burns. For that reason, Rockford valve safety trains feature industrial-grade construction and are universally wired to accept most North American control systems. Optional features allow for common adaptations such as safety valve proving, climates down to -20 deg F, 230V controls, lockable valves, and pilot-line assemblies. The designs feature industry-leading components and are engineered to meet or exceed NFPA, NEMA, CSA, UL, FM and other globally recognized safety standards.

In addition to the production of standardized and customized valve safety trains, this division offers combustion safety training, on-site risk assessments, annual inspections, pre-acquisition audits, customized engineered systems, quality installation and post-sale support. This turnkey approach allows companies the convenience of one-stop shopping for all of their combustion safety needs.

“We are best known for providing turnkey machine safeguarding systems that reduce risk and help prevent industrial injuries in some of the largest companies in the world,” said Joe Nitiss, the chief executive officer of Rockford Systems. “This makes our entry into combustion safety a natural evolution as we are able to replicate similar turnkey systems for thermal-processing customers.”