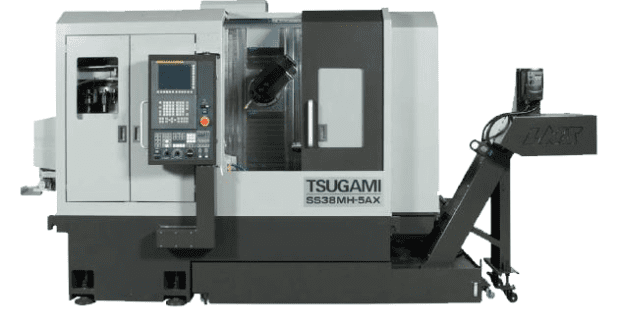

Machine Highly Complex Parts from Bar Stock Complete in No Time

The Tsugami SS38MH-5AX sliding headstock lathe with B-axis from Tsugami/Rem Sales offers full 5-axis machining with a FANUC 31i-B5 control.

Posted: April 25, 2019

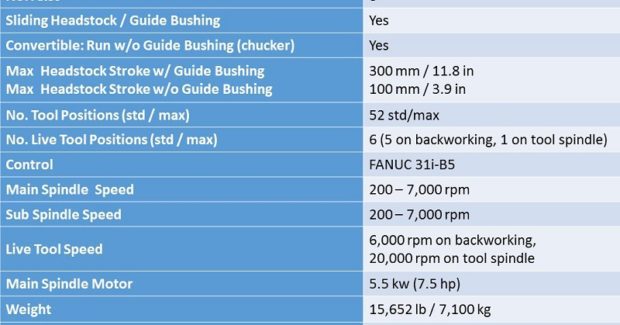

The Tsugami SS38MH-5AX sliding headstock lathe with B-axis from Tsugami/Rem Sales, LLC (Windsor, CT) is a chucker-convertible, high-performance automatic CNC Swiss-type CNC lathe that offers full 5-axis machining with a FANUC 31i-B5 control that makes it possible to machine the most complex shaped parts from bar stock complete in no time. This corresponds to heavy-duty cutting by dual contact holder using CAPTO C4. This extremely versatile machine weighs in at just over 15,000 lb and has a backworking overlap with live tool capability that allows for multiple tools in the cut and shorter cycle times. It is equipped with a total of 52 tools, including a 40-tool magazine, ten tools on the back tool post, five modular type live tools on back tool post for optimum allocation of machining capability, and two optional tools on the deep hole drill holder. Linear glass scales on the X1, Y1, and Z1 axis slide are standard for ensured high accuracy machining and repeatability.

Tsugami/Rem Sales, LLC, a division of Morris Group, Inc., 910 Day Hill Road, Windsor, CT 06095, 866-224-8576, [email protected], www.remsales.com.