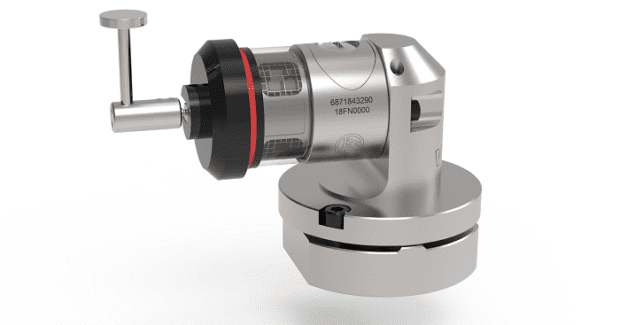

Horizontal Tool Setter with Optical Transmission

For use on vertical machining centers, the horizontal VOTS 90 deg optical probe from Marposs provides unidirectional repeatability of 1 μm that is ideal for presetting and verification of breakage, wear and integrity checks and length and diameter measurements on small cutting tools.

Posted: April 30, 2019

The expanded TS line of contact tool setters from Marposs Corporation (Auburn Hills, MI) now includes the VOTS 90 deg optical probe for use on vertical machining centers. Due to its horizontal design, this probe can be installed on the machine table outside the working area to save machining space without compromising on tool inspection. The low measurement force along the Z-axis makes this probe ideal for presetting and verification of small tools. The VOTS multi-channel unit is used to carry out breakage, wear and integrity checks and length and diameter measurements on cutting tools, offering unidirectional repeatability of 1 μm. It can be used for twin applications in which part and tool checks are managed by a single VOI optical receiver. VOTS 90 probes feature an innovative modulated transmission technology to ensure high immunity to interference. Relying upon optical transmission, these probes eliminate the need for cables to simplify setup and installation. The TS line of tool setters is also available in hard-wired and radio transmission versions. All versions are equipped with an LED probe body that indicates the operating state.

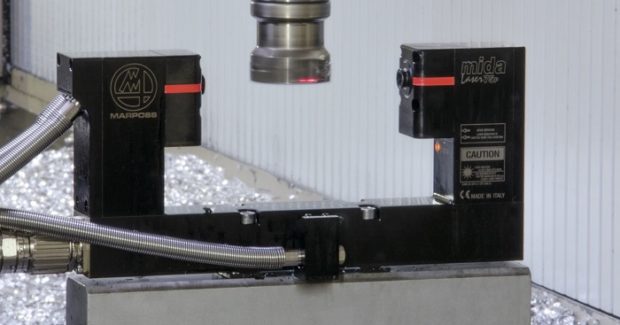

Marposs also offers the Mida Laser 75P Hybrid tool setter that combines a non-contact laser and touch probe in one system. While the laser enables measurement and checks on high-speed rotating tools, the laterally mounted touch probe monitors non-rotating, lathe tools. The incorporated Mida A90 touch probe is available with three to five tool contact surfaces and one or more LEDs to visually detect the electrical contact between the tool and the probe. Typical uses of the Mida Laser 75P Hybrid include tool identification, tool breakage detection, pre-setting of unknown tools, tool dynamic length and diameter measurement, tool wear compensation, tool cutting edge profile integrity verification and machine axis thermal drift compensation. Suited for unmanned operations, the unit presets tools in the machine and updates tool table data automatically. All of this helps to reduce machine downtime and scrap, increasing productivity and production quality.

The Mida Laser 75P Hybrid features an efficient, three-stage shutter group that protects the system from dirt. When not performing measurements, the shutter is mechanically closed to prevent dirt from reaching the emitter and receiver lens while during the measurement cycle, a patented Air Tunnel Effect enables the measurement and verification of tool dimension, wear and breakage, even in the presence of coolant. A microprocessor, integrated into the unit’s electronic interface, elaborates the signal received, filtering noise coming from coolant and chips. This system is available with a “collimated” or “focused” laser beam. The focused model is essential for cutting edge integrity verification and length measurements of chisel or rounded nose tools, or for tools with a diameter of less than 1 mm.

Marposs Corporation, 3300 Cross Creek Parkway, Auburn Hills, MI 48326, 248-370-0404, Fax: 248-370-0991, www.marposs.com.