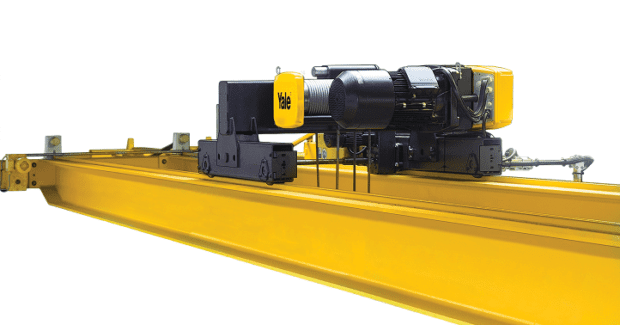

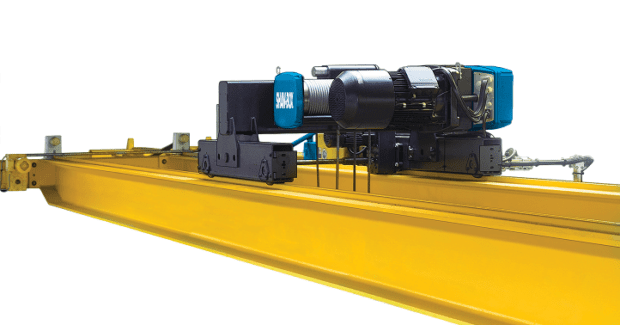

Double Girder Hoists for Precise, Stable Handling of Heavy Loads

To handle heavy loads safely and precisely in a wide variety of applications with space limitations, Yale YK and Shaw-Box SK stand-alone double girder wire rope hoists from Columbus McKinnon can lift up to 30 tons using a low-headroom trolley and UL508A-approved controls for highly stable hoist, trolley, and bridge motions.

Posted: April 30, 2019

Double girder hoists add stability for the production and transportation of heavy loads and enable more frequent operation. Highly stable, with the ability to handle loads safely and precisely, double girders offer increased hook height, improved headroom dimensions, and wider crane span capabilities. Yale® YK™ and Shaw-Box® SK™ stand-alone double girder wire rope hoists from Columbus McKinnon Corporation (Getzville, NY) can lift up to 30 tons using a low-headroom trolley that is ideal for a wide variety of applications with space limitations. Yale YK and Shaw-Box SK double girder hoists use Magnetek IMPULSE®·G+ Mini variable frequency drives (VFDs) with extended lifting capacities. For trolley motion, compact IMPULSE·G+ Mini drives for double girders have capacities up to 30 tons. This drive is a low horsepower crane control that enables easy monitoring and adjustments of hoist performance. For hoist motion, IMPULSE®·VG+ Series 4 drives for double girders have capacities up to 15 tons.

UL508A-approved controls for hoist, trolley, and bridge motions are now standard with Yale YK and Shaw-Box SK wire rope hoists. After undergoing extensive testing, these controls have been determined to meet this higher protection standard. Combining Magnetek VFDs with Yale YK and Shaw-Box SK creates one-of-a-kind, intelligent lifting systems.

Columbus McKinnon also offers NEC-approved, Class I, Division 2 explosion-protected Stahl CraneSystems brand SH Ex wire rope hoists in five frame sizes with 26 load capacity variants, from 1,000 lb to 30 tons in deck mount, monorail trolley, and double girder trolley models for use with standard, customized, or special crane applications. “Based on the SH wire rope hoist platform, the explosion-protected SH Ex models allow for wider use in applications and industries with potentially hazardous environments,” said Thomas Kraus, the global product manager of wire rope hoists at Columbus McKinnon. “Complying with ATEX, IECEx and NEC standards, the SH Ex wire rope hoist offers reliable operation, high efficiency, and increased safety.” Custom-made SH Ex designs with lifting technology and components will comply with NEC approvals for Class I, Division 2, Groups A, B, C and D hazardous locations with Temperature Class T4. NEC approvals are adoptable standards that signify the safe installation of electrical wiring and equipment in hazardous locations that may include flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors.

These explosion-protected models are also available with ATEX and IECEx approvals for EX Zone 1, Zone 2, Zone 21, or Zone 22 hazardous locations. ATEX compliance, required in the European Union, certifies that the SH Ex is safe to use in potentially explosive areas with flammable gases or dust. IECEx equipment certification signifies that the SH Ex conforms to international safety standards for environments where a potential exists for explosions. The SH Ex is also available with spark-resistant features such as coated hooks, brass wheels, and brass drop lugs on trolley.

Columbus McKinnon also offers the patent-pending CM Tornado 360 deg ratchet lever hoist with 9-ton lifting capacity. Ergonomically designed for increased safety, it allows the operator to be more productive with significantly less effort compared to conventional ratchet lever tools. The CM Tornado 360 deg redefines ratchet lever hoists with its unique Sidewinder lever handle that features a 360 deg rotating lever and a fold-out revolving handle. Working in unison, these integrated components allow the operator to realize the full potential of 360 deg rotation while working in a safe and ergonomic position. This helps reduce repetitive wrist action experienced with the pulling operation of traditional lever hoists, letting the operator utilize a full 360 deg range of motion to work up to 12X faster. Other features include a highly visible, easy-to-use directional indicator located on the handle that clearly shows the operating direction as lifting, lowering or neutral.

This hoist also has a cast chain end stop that allows the user to easily position the chain in free-chaining mode, preventing it from entering the liftwheel and jamming the hoist. Bolt-on swivel hooks with nylon locks help users comply with ASME B30.21 and B30.10 inspection requirements. The CM Tornado is available in ¾ ton, 1½ ton, 3 ton, 6 ton and 9 ton capacities with standard lifts up to 20 ft. Additional lifts are also available. The hoist features an industry-leading lifetime warranty and meets ASME B30.21 and EN 13157 manually-operated hoist standard. Outside of the North American market, this hoist is marketed under the Yale brand as the Yale Ergo 360 deg™ ratchet lever hoist.

Columbus McKinnon Corporation, 205 Crosspoint Parkway, 716-689-5400, Getzville, NY 14068, www.cmworks.com.