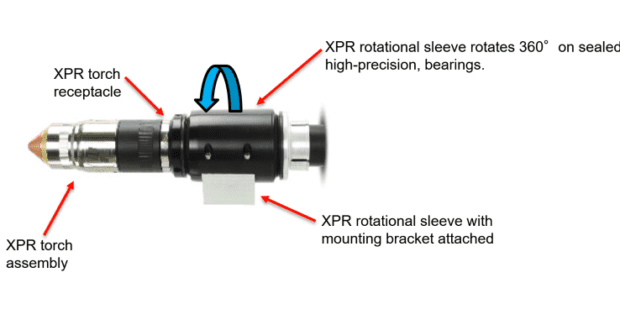

Rotational Torch Sleeves for Bevel and Robotic Cutting Applications

To greatly increase torch life and productivity during high-flex cutting of mild steel, stainless steel, and aluminum, rotational torch sleeves from Hypertherm rotate 360 deg clockwise or counter-clockwise while the torch and lead sets remain axially fixed.

Posted: March 6, 2019

Three new torch sleeves for XPR plasma cutting torches and lead sets from Hypertherm Inc. (Hanover, NH) allow the torch and lead sets to remain axially fixed while the torch-holding device rotates 360 deg in either a clockwise or counter-clockwise direction to greatly enhance torch lead life in high-flex applications. These new sleeves – available in short, medium, and extended lengths – are ideal for bevel or 3D/robotic cutting applications when using either an XPR170™ or XPR300™ X-Definition™ plasma system. The sleeves include several engineering advances: An outside diameter of 76 mm (3 in) allows for an increased wall thickness and eliminates compression caused by clamping. Pre-sealed, high precision bearings reduce axial play by 90 percent and radial play by 81 percent to keep out dirt and other particulates associated with plasma cutting and greatly extend the life of the sleeve and lead system.

When used with specialized Hypertherm robotic/bevel lead sets, the rotational sleeve will afford users an especially robust industrial system in applications requiring frequent rotational flexing when cutting with an XPR170 and XPR300, the only two X-Definition capable systems in the world. A combination of engineering advances and refined high definition plasma processes help X-Definition class plasma deliver unmatched plasma cut quality on mild steel, stainless steel, and aluminum. Laboratory testing shows ISO-9013 Range 2 cut quality on thin mild steel and extended ISO Range 3 cuts on thicker metals. Both X-Definition systems contain patent-pending processes, such as Vented Water Injection™ (VWI), plasma dampening and Cool Nozzle™ technologies for squarer cut edges, markedly less angularity, and excellent surface finish on non-ferrous metals like aluminum and stainless steel. At the same time, these systems cut faster and use power more efficiently than earlier HyPerformance® HPR260XD® systems.

Hypertherm now ships new consumable starter kits for their XPR X-Definition plasma systems that are available with or without a torch for mild steel and non-ferrous cutting applications. These kits include a variety of consumables to allow for cutting at different amperages, using all of the gas process types supported by the XPR170 and XPR300 systems. The consumables contain several patent pending technologies to improve consumable life and cut quality. Examples include Cool nozzle and Arc response technology™, the latter of which protects consumables from the negative impact of ramp down errors, a regular occurrence in real-life cutting. By reducing the impact of ramp down errors, XPR consumables can last up to 3X longer than those on older generation systems. XPR consumables are also designed with ease of use in mind: An EasyConnect™ feature allows operators to quickly plug the torch lead into the torch connect console without the use of tools, while a patent pending QuickLock™ electrode delivers easy quarter turn tightening to further reduce setup time.

Another new design feature is a quick change torch that enables an operator to rapidly change torches with just one hand. “Whether you are cutting mild steel, stainless steel, or aluminum, these new starter kits will make it easy for XPR users to get all of the consumables they need in one convenient kit,” said Martin Geheran, the product manager for plasma torches and consumables. “We think users will also enjoy the convenience of the kits that come with a torch because it will give them the option of having a second torch or even multiple torches, pre-loaded with consumables for even faster change-outs.”

Hypertherm Inc., PO Box 5010, Hanover, NH 03755-3124, 603-643-3441, www.hypertherm.com.