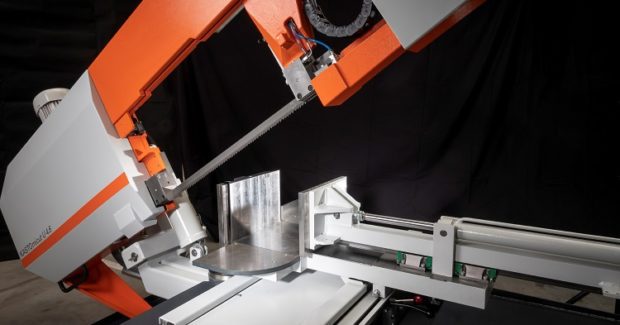

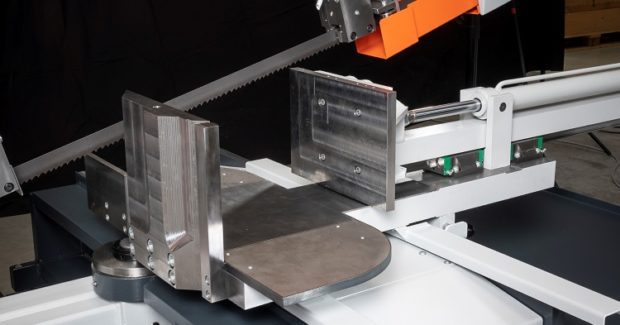

Precision Cut to Length and Miter Cutting of Metal Tubes, Sections, Solids

Manual, semi-automatic and fully automated KASTOmicut swing-frame bandsaws from KASTO deliver high precision cuts on different materials and hard-to-machine alloys, all with an attractive price-performance ratio.

Posted: March 5, 2019

For cutting metal tubes, sections and solid materials to length and for miter cutting, KASTOmicut swing-frame bandsaws from KASTO, Inc. (Export, PA) deliver high precision on different materials and with an attractive price-performance ratio. For single-sided miter angles and cuts from 0 to +60 deg, the Die KASTOmicut E 4.6 uses a hydraulically-controlled feed to saw round material up to 335 mm diameter and flat material up to 460 mm x 335 mm. Blade and material tensioning is carried out mechanically. Cutting speed can be continuously adjusted between 20 m/min and 110 m/min for processing different material qualities. The KASTOmicut U 4.6 can process flat stock up to 520 mm wide by clamping the material with a horizontal hydraulic vice that simplifies handling to increase output during small batch production. Its continuously adjustable cutting speed lies between 12 m/min and 150 m/min, with continuously adjusted miter cuts possible from -45 deg to +60 deg. Its heavy and torsionally-rigid welded saw frame provides extreme stability for the saw blade, ensuring excellent cut quality on even hard-to-machine materials.

For shops who saw smaller workpieces, the KASTOmicut P 1.8 saw has a cutting range of up to 180 mm and is suitable for straight and miter cuts from 0 to +45 deg. It features manual material clamping with an easy-to-operate and easily adjustable clamping device. Its saw blade is also tensioned manually, and its feed rate is determined by manually guiding the saw frame, with a cutting rail to support material. An efficient three-phase motor delivers a drive power of up to 1.5 kW for high cutting quality. This saw has small dimensions, excellent accessibility, and can be moved by forklift into position as needed. Its shortest possible cut length is 6 mm to 10 mm and, with a remnant piece length of 15 mm to 30 mm for individual cuts, users can maximize material usage. A highly efficient worm gear mechanism provides top performance and ensures a constant cutting force for excellent results with all materials.

KASTO Maschinenbau GmbH & Co. KG, Industriestr. 14, 77855 Achern, Germany, +49 (0) 7841 61-0, Fax: +49 (0) 7841 61-111, [email protected], www.kasto.com.

KASTO, Inc., 3002 Venture Court, Export, PA 15632-8949, 724-325-5600, www.kasto.com.