High Efficiency Dust Collection for Fabrication Shops

Using HemiPleat technology, the Gold Cone X-Flo filter cartridge from Camfil stays cleaner and lasts longer than conventional pleated filters in welding, thermal spray, plasma cutting, laser cutting and abrasive blasting operations.

Posted: March 25, 2019

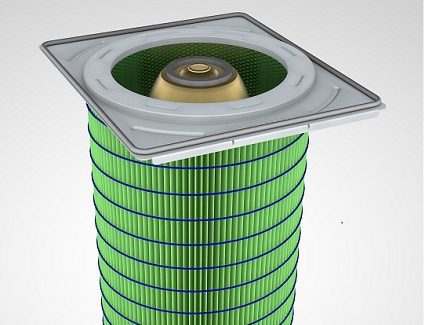

The Gold Cone™ X-Flo (GCX) Filter Cartridge from Camfil APC (Jonesboro, AR) is for high efficiency industrial dust collection for shops involved in welding, thermal spray, plasma cutting, laser cutting and abrasive blasting operations. Building on the proven performance of HemiPleat® technology, GCX filters stay cleaner and last longer than conventional pleated filters. GCX filter cartridges use a proprietary inner pleat pack with an open-bottomed, inner-cone of media that greatly expands the usable surface area of the cartridge. Because the HemiPleat design exposes more media to the airstream, more dust is loaded on the filter and released during pulse cleaning. These filters are available in a selection of regular or nano-fiber media and are guaranteed to meet EPA particle emission requirements. They were designed specifically for the X-Flo (GSX) dust collector. The unique location of the GCX filter inside the collector enables more downward-facing media than standard, competitive systems.

The cone is configured so that pulsed air is evenly distributed top to bottom along the outer pack of the filter and down through the inner cone pack. That means with each pulse the GCX cone cartridge ejects more dust out of the collector straight down to the hopper. This design offers an advantage over horizontal-style filters that pulse most of the dust back onto adjacent filters. Used together, the GSX collector and GCX filter is one of the most powerful and cost-efficient dust collection system on the market. The system maximizes airflow while minimizing filter change-outs, compressed air usage and energy costs. GSX dust collectors are ideal for industrial applications that produce or process fine, fibrous and heavy dusts and fumes. GSX dust collectors exceed OSHA mandates for indoor air quality and are tested to meet NFPA and ATEX standards. They are available with many explosion protection options, including explosion vents, isolation valves, integrated safety monitoring filters and fire-retardant filter cartridges.

Camfil APC, 3505 South Airport Road, Jonesboro, AR 72401, 870-933-8048, camfilapc.com.