Designing a Metalworking Coolant for Multiple Applications – in Half the Time

Without DoE, chemists would have taken twice as long to develop the extremely biostable HOCUT 8000 coolant and been lucky to achieve its same levels of performance in extending sump life and eliminating the need for costly sump-side additives. Here’s an inside look at how they did it.

Posted: March 1, 2019

By Dr. David Slinkman and Dr. Yixing (Philip) Zhao

The metalworking fluids market is a $9 billion plus segment of the specialty chemicals business that includes cutting fluids, forming fluids, protection fluids, and quenching fluids. One of the most important trends in cutting fluids is towards products that work with multiple metals to reduce the number of fluids needed by a manufacturer. Developing fluids that work with multiple materials adds another layer of complexity to a design process that is already challenged by the need to pick out and determine the optimal proportion of up to 25 different formulation additives. Houghton International Inc. (Norristown, PA) used Design of Experiments (DoE) to develop a new multi-metal cutting fluid that handles steel, cast iron, aluminum and cast aluminum in half the time required by the company’s previous development methods.

DEVELOPING A NEW CUTTING FLUID

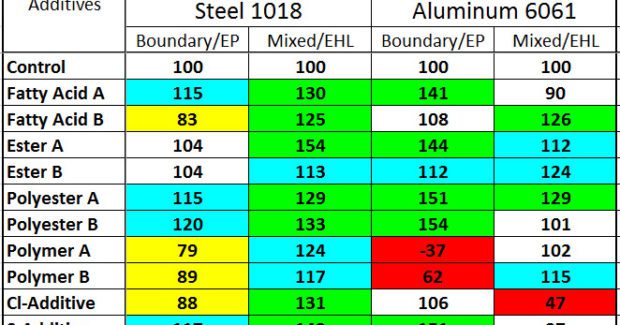

The first stage in the development process for a new cutting fluid is to investigate individual lubricity additives that reduce friction between the cutting tool and workpiece. In this case, one factor at a time (OFAT) studies were used to screen potential lubricity additives. The performance of these additives was determined with a test that measures the coefficient of friction between a test specimen and a pin with the additive applied. The measured coefficients of friction were compared to a control value to determine lubrication efficiency relative to the control. Each selected lubricity additive was tested on different metals and at different application conditions. From the test results, lubricity additives were selected for the new product formulations based on their ability to provide good lubricity on steel or aluminum or both (see Chart 1).

Typically, a number of additives are used in the lubricity package of a cutting fluid. With many different possible additives to consider for a new cutting fluid, chemists in the past relied on OFAT methods to identify the right formulation for a new product. This approach provides a quick way to get a rough comparative measurement of additive performance. The problem with the OFAT method at this stage is that three or four repeats of tests or measurements are needed to evaluate the effects of each additive. But even after performing these tests, chemists are unsure whether the difference in performance between different additives is statistically significant. They also have no way to understand possible interactions between the additives without running many more samples. As a result, this approach is time-consuming and leaves chemists uncertain as to whether they have achieved the best formulation.

IMPLEMENTING DESIGN OF EXPERIMENTS

Houghton has improved their abilities to develop cutting fluids and other new products over the past five years by applying DoE to the product development process. In moving to DoE based development, managers wanted to ensure that their chemists would continue to spend nearly all their time on chemistry and not become bogged down or distracted dealing with statistical software. The company accomplished this goal by selecting statistical software that is designed for use by people without any statistical background yet still provides all of the analytical power needed for designing specialty chemical products. Design-Expert® software from Stat-Ease, Inc. (Minneapolis, MN) makes it easy to train chemists in its use and easy to convince them to use it. We now have users in many of our global development centers. Stat-Ease provides all of the different experimental designs, analytical methods and statistical reports that we need to develop successful products.

SELECTING KEY COMPONENTS IN A MIXTURE EXPERIMENT

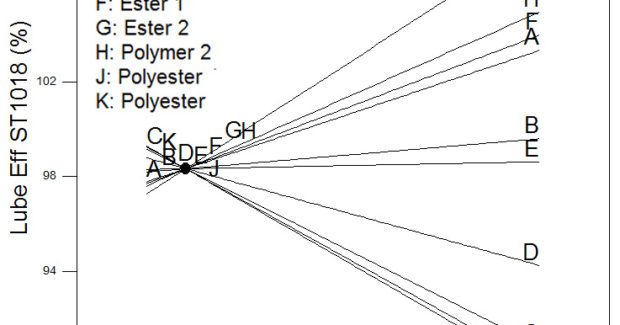

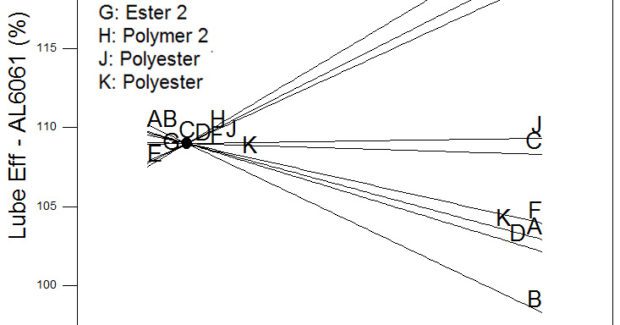

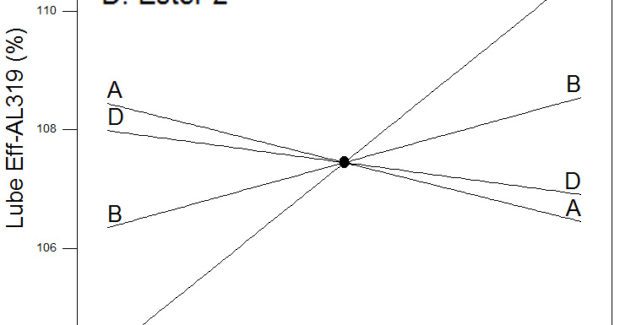

After the OFAT method was used to identify promising additives, mixture design and analysis tools were used to select the best four or five additives for more comprehensive analysis. In developing the new multi-metal cutting fluid, the chemists started by calling up the results of previous OFAT studies of ~ 40 different additives. They selected the ten most promising additives and set up a mixture experiment in Design-Expert.1 This DoE required 25 runs, far fewer than would have been needed to evaluate the impact of each additive individually over a range of concentrations using the OFAT method. The lubricity tests of these mixtures were performed on 1018 steel, 6061 aluminum and 319 cast aluminum. Multicomponent mixture design reduces the number of experiments required to develop formulations. All variables are included and simultaneously varied in the 25 runs – the statistical analysis sorts out the individual effects of each variable as well as their statistical significance. The analysis showed that some additives are good only on one type of metal while others are good on both (see Graphs 1, 2).

Based on the mixture experiment, the chemists selected four lubricity additives that provide the best overall performance for further study. This would have required at least twice as many samples using the OFAT method.

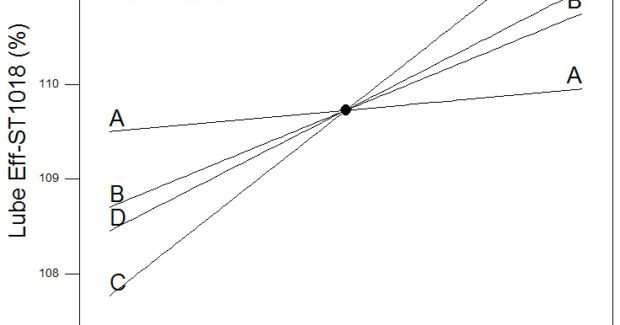

OPTIMIZING THE FORMULATION WITH FRACTIONAL FACTORIAL ANALYSIS

The chemists then performed a fractional factorial experiment on the four additives. They chose a template that would uncover interdependencies between variables. For example, it’s not uncommon for an additive to have only a minor impact on a property such as lubricity. However, it is noteworthy if that impact increases significantly when another additive is put into the mix. In-depth factorial experiments require additional runs, but the company was able to obtain the best of both worlds by using a mixture experiment to first narrow the field to just a few stellar additives so that the follow-up factorial could be performed with only ten runs. The experimental results included a recommended optimized formulation that takes the direct impact of the additives as well as the interactions of the additives into account. It’s important to note that this optimized formulation was not one of the samples drawn up for the experiment but rather was calculated by Design-Expert based on the first and second order effects of the additives as determined over the course of the experiment.

The chemists created and tested the lubricity additive formulation recommended by statistical analysis and it delivered results close to the DoE predictions. They made further modifications to the formulation to develop a final lubricity additive package that best meets the requirements of the market, then used similar methods to select additional additives for the multi-metal cutting fluid including emulsifiers, corrosion inhibitors, preservatives and others. Based on the results of these experiments, the chemists developed a final formulation for the product platform that is optimized to deliver high levels of performance on steel, cast iron, aluminum and cast aluminum (see Graphs 3, 4).

In Q4 2017, Houghton officially launched the HOCUT® 8000 Series: state-of-the-art technology designed to improve users’ operational efficiency, part quality and surface finish. These coolants have built-in detergency, run clean and provide excellent wetting which reduces consumption due to drag out, lowering customer fluid costs. They also have superior dispersibility, improving chip removal thereby minimizing downtime, excellent emulsion stability and low-foaming characteristics resulting in consistent lubrication and heat transfer performance. HOCUT 8000 coolants are extremely biostable, so they extend sump life and eliminate the need for costly sump-side additives. This new product line has been a success in the marketplace. Management estimates that it would have taken at least twice as long to develop the product using conventional methods and that they would have had to be very lucky to achieve the same levels of performance that were achieved with DoE.

References

1. Mark J. Anderson, Patrick J. Whitcomb, Martin A. Bezener, “Formulation Simplified: Finding the Sweet Spot through Design and Analysis of Experiments with Mixtures”, Productivity Press; 1st edition (April 1, 2018).

Dr. David Slinkman is the senior vice president of global research and technology and Dr. Yixing (Philip) Zhao is a senior research scientist and Innovation team leader at Houghton International Inc., 945 Madison Avenue, Norristown, PA 19403, www.houghtonintl.com.

Stat-Ease, Inc., 2021 East Hennepin Avenue, Suite 480, Minneapolis, MN 55413-2726, 612-378-9449, Fax: 612-378-2152, [email protected], www.statease.com.