Hybrid Press Brake Reduces the Cost of Forming Difficult Part Shapes

This quiet running 150 ton hybrid press brake from Cincinnati Incorporated uses bend simulation software with 3D part views, interlocked frame members, programmable ram tilt and an exclusive six-axis linear motor backgage to provide the productivity and versatility needed for demanding fabrication jobs.

Posted: February 19, 2019

A new 150 ton hybrid press brake from Cincinnati Incorporated (CI; Harrison, OH) brings the advantages of servo-motor pump technology to hydraulic and electric drive press brakes. This new drive allows the machine to run quieter and reduces operating cost with lower energy consumption and simplified maintenance. Unlike fixed-speed induction motors that drive the pump in conventional hydraulic systems, a servo-motor driven pump only runs during the working portion of the stroke, conserving energy while the ram is stationary. In addition to energy savings, it requires less than 30 gal of fire resistant, readily biodegradable hydraulic fluid. This hybrid press brake provides the productivity and versatility required by modern fabrication shops. Job setups are assisted with a graphical display of tool locations, photo and video attachments, hydraulic tool clamping and programmable crowning. Ram speed of 550 ipm and precision ram repeatability of ±.0002 in assure fast and consistent production. A generous 14 in stroke and 21 in open height tackle challenging part shapes and tool heights.

New features found on this press brake are an ergonomic sliding overhead control arm, unique built-in storage cabinets, LED lighting, protective cylinder covers and side and rear guards. CIberlink generates daily log files of machine production with the ability to monitor machine status in real-time on a desktop dashboard. This hybrid design includes a field-proven 22 in touchscreen control, bend simulation software with 3D part views, interlocked frame members, programmable ram tilt and an exclusive six-axis linear motor backgage. This hybrid press brake is backed by factory-trained field service technicians and factory phone support with online diagnostics.

The newly enhanced 60 ton Autoform hydraulic press brake from CI is their first compact hydraulic machine available with a six-axis backgage and a full 6 ft long bed. “Many fabricators now realize the benefits of routing smaller parts to compact machines to free up traditionally-sized machines for larger and heavier components,” said Todd Kirchoff, the manager of vertical motion products for CI. “The small footprint of this hydraulic press brake complements our line of compact electric press brakes and allows for more efficient production of smaller parts.” Its base dimensions are 83 in wide x 48 in deep. The machine includes a swinging pendent control that can be positioned in front or at the side. Key features include exceptional ram repeatability (±0.0004 in), longer stroke length (11 in) and fast forming speeds (programmable from 1 ipm to 120 ipm). The available six-axis backgage gives it the ability to excel at fabricating small, complex parts with greater throughput than a larger machine.

The Autoform incorporates many of the same advanced features introduced on the electric Goform press brake, including innovative Angle Measuring technology that automates the manual method of measuring and adjusting bend angles. During production, a high-speed digital camera that is mounted to the machine captures images of the bend. The images are analyzed and the press is commanded to continue bending until the part is within the desired tolerance. The important operator interface for this feature was developed in-house by CI software engineers. Feedback from equipment users resulted in a unique easy-to-use interface that enables inexperienced operators to produce quality parts with minimal instruction. The 3D control graphics and available six-axis backgage make this sleek, compact 60 ton hydraulic press brake ideal for forming the complex shapes often created with advanced solid model design software. Operators can reach the machine controls with minimal movement.

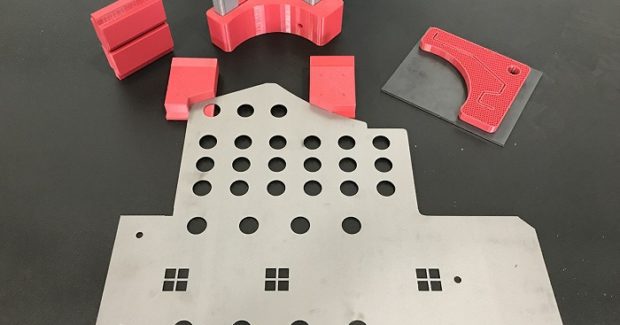

A trio of 3D-printed press brake process enhancements – printed upper and lower airbend tooling, printed backgage fingers and a printed inspection gauge – from CI create a new productive link between metal fabrication and additive manufacturing. 3D printing of standard American-style upper and lower airbend tooling is particularly useful for specialized jobs, prototyping, or short production runs, eliminating associated engineering and production times that cause delays in getting these types of jobs up and running in a timely manner. While many parts have complex shapes and contours, there can be challenges and delays in gaging properly and securely. With specialized 3D printed fingers, these challenges are eliminated as difficult parts are gaged in a fast, simplified, easy way. With 3D printed inspection fixtures, all facets of a formed part can be checked at once, dramatically reducing the time spent measuring. This is especially ideal for longer parts that require multiple check points, or for cross sections with shallow bends.

These innovations are 3D printed using PLA, a milk-based plastic that offers a green, environmentally-friendly benefit. Prototype fabricators working in 12 ga or thinner materials are ideal for this new technology, as are fabricators forming smaller specialty parts. “This is very much a design tool that unlocks new fabrication possibilities for our customers,” said Mark Watson, a senior product specialist of vertical motion products at CI.

Cincinnati Incorporated, 7420 Kilby Road, Harrison, OH 45030, 513-367-7100, [email protected], www.e-ci.com.