Got Scrap?

Though scrap metal is often regarded as a waste or by-product from fabrication operations, it is actually a viable revenue source – in fact, it is the second largest revenue source next to the finished product. This is why shops should have a formal management system in place to maximize the revenue they generate from scrap.

Posted: February 18, 2019

All shops engaged in bending, cutting, stamping, forming, welding or other metal fabrication operations share one thing in common: they all generate scrap to some extent, whether in small amounts or large quantities. Though scrap metal is often regarded as a waste or by-product from production, it is actually a viable revenue source – in fact, it is the second largest revenue source next to the finished product. Just as most shops follow established procedures to decrease production costs, increase efficiency and ensure high quality for the products they manufacture, they should also have metrics in place to maximize the revenue they generate from scrap. This can be accomplished by implementing a scrap management program that is focused on keeping scrap handling costs low, increasing the return on investment or revenue from scrap metal sales, and doing so in an environmentally-friendly manner.

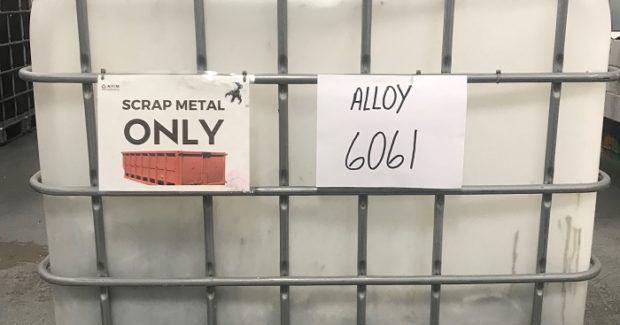

SCRAP ALLOY SEGREGATION

One of the primary goals in scrap management is to ensure that the highest possible financial return is received for the scrap metal. The best way to do this is through scrap alloy segregation, which includes:

- An alloy labeling system.

- Employee training or review.

- A detailed scrap metal packing list.

If followed properly, these steps will combine to separate scrap alloys correctly for a higher rate of return. The labeling system places clearly visible labels on all scrap handling equipment and/or containers, including hoppers, totes, bins, pallets, roll-off containers, etc. Each label should have an alloy type clearly written on it to designate and display the specific alloy assigned to that respective piece of handling equipment or container. Segregation basics/employee training is essential to make any scrap alloy segregation program successful. Management must teach, review and follow up on all aspects of the segregation program with every employee involved in the handling of scrap metal. One of the key employees that will make this system successful is the machine operator: They should be responsible for using the container that is labeled for whatever alloy they are fabricating. For example, if they are processing 304 stainless steel, then they must use the container labeled for 304SS.

Because the goal is to keep all scrap alloys segregated, it is also important to prevent cross-contamination from occurring when the operator changes from using one type of alloy to another. This can be prevented by having the operator completely clean the machine and area free of the last alloy used before switching to another. Cross-contamination not only significantly harms the value of the scrap, in some cases it can render material all-together worthless. For instance, consider when 304 stainless is mixed with an aluminum alloy. A mill or end consumer will only melt the type of alloys they are looking to produce, which means an aluminum mill does not want or need any type of stainless steel mixed in with the scrap aluminum they are melting. Finally, before selling the scrap, a good practice is to write a detailed packing list that includes records of both the alloy type and grade. Also, if a scale is available, it is important to weigh each commodity and document it on the packing list. Providing a packing list such as this shows the scrap buyer that you are aware of the alloys you have and, if weighed, the exact quantity of each.

IN-PLANT SCRAP HANDLING

Many fabricators use self-dumping hoppers to transport their scrap turnings/shavings to a roll-off container kept outside. While this method is popular and effective, there are some negative aspects: One is the labor required to transport the hoppers back-and-forth from the machine tool inside to the roll-off outside, a time consuming process that can hold the machine tool idle and non-productive. The other is storing the scrap turnings in roll-offs outdoors, where cutting fluid runs out of the roll-off container all over the lot. Besides being an environmental eyesore, wet turnings (either by fluid or rain) can also greatly reduce the financial value of the scrap. An alternative method of in-plant scrap handling that can save labor dollars, increase scrap value and keep the facility environmentally friendly is to replace the use of self-dumping hoppers and a roll-off container with 4×4 plastic totes, which are nicknamed “scrap cubes.” Although this technique may not work for all shops, it can provide an inexpensive way to help others maximize the efficiency of their scrap management program:

The first step is to acquire the scrap cubes that are needed. These totes can be purchased inexpensively and, in some instances, acquired at no cost. Some companies are more than willing to give the containers away when they are done using them. Two things must be done before using these totes as scrap equipment: First, make sure they are cleaned and safe for reuse – it is best to pass on any that have been used to hold something hazardous. Second, simply cut the top off with a zip saw. The advantages of using the scrap cubes can far exceed that of using self-dumping hoppers and roll-offs. Cubes have drain valves, can be stacked and easily stored inside, and can be changed out with a pallet jack instead of a forklift. A scrap cube is placed beside each machine tool to collect its scrap turnings, no different than a dump hopper. When full, however, the machine operator can use a pallet jack to take the loaded scrap cube and swap it with an empty. This quick-change method is more efficient than having to find a forklift operator to pick up, empty and bring back the dump hoppers. It also reduces machine downtime.

Empty cubes can be stored outside, but to keep the metal turnings dry, full totes should be kept inside. Scrap cubes can be stacked both empty and full to save space. Many shops take advantage of the drain valve on these use cubes, opening it to drain and reuse the cutting fluid, which reduces their supply costs and fluid disposal costs. Draining the fluids can also help keep the scrap turnings dryer and help prevent or reduce high moisture deductions when the turnings are sold.

One machine shop that realized these types of savings from swapping over to scrap cubes is KRC Power Steering (Kennesaw, GA), a manufacturer of power steering and serpentine pulley systems. “Since swapping to these totes, we’ve saved on a couple of different things,” explained Cody Haskins, the vice president of KRC. “First, we can now recycle fluid that was being wasted into our past containers. We were using a 40 yard roll-off and paying a surcharge of 1,000 gal of fluid disposal per container. By using these cubes, we save roughly 10 gal of clean coolant per tote that we recycle right back into the machine. This saves around $500 a month on coolant. Second, we were using roll-around hoppers with a forklift attachment and dumping them into an outside container. Every minute those machine tool spindles are not turning is money lost. We lost roughly 45 minutes to one hour twice a week for three employees at 1.5 per machine per minute, on four to six machines. Now we save around $550 per week by utilizing the totes.”

Haskins added, “So overall, we get more for our chips because we don’t have to pay for coolant in the chips, we save money on buying new coolant, and we save money in labor to dispose of the chips. That’s excellent.”