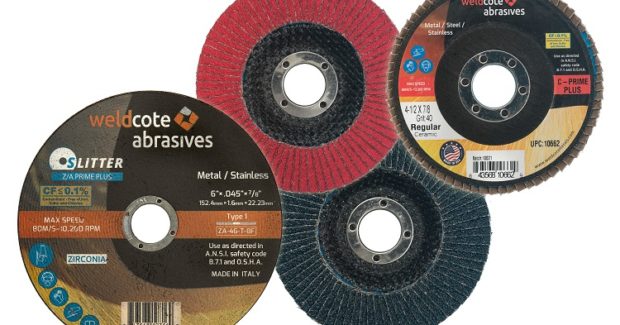

Flap and Quick Change Discs for Effective Grinding, Cutting and Other Applications

Metalworking abrasives from Weldcote include flap discs, quick change discs, Korner flap discs, resin fiber discs, flap wheels, cutting wheels, pipeline wheels and grinding wheels that are formulated for a wide variety of metals.

Posted: February 22, 2019

A comprehensive line of more than 900 metalworking abrasives from Weldcote Metals (Kings Mountain, NC), a division of Zika Industries, Ltd. (Anyksciai, Lithuania) includes many that are made in the U.S. at their state-of-the-art production facility in Niles, IL. Their line of flap discs made in the U.S. has multiple bonding and backing systems, backing plates and design shapes to handle a wide variety of applications. The flap disc materials, formulated for a wide variety of metals, include ceramic (C-Prime and C-Prime Plus), zirconia (Z-Prime and Z-Solid), aluminum oxide (A-Prime) and aluminum (ALU-Prime). Rounding out this offering are U.S.-made quick change discs, as well as Korner flap discs, resin fiber discs and flap wheels. High quality, resin-bonded abrasives are now available in the U.S. through an exclusive relationship with a renowned Italian abrasives manufacturer (the PRIME brand), as well as a partnership with a well-known Chinese supplier (the SOLID brand). This abrasive program also covers a full line of cutting wheels (branded as SLITTER), Notch pipeline wheels and grinding wheels.

Weldcote Metals, 842 Oak Grove Road, Kings Mountain, NC 28086, 704-739-4115, Fax: 704-739-6116, weldcotemetals.com.