Faster Inspection of Stamped, Molded or Machined Parts

Altera high-speed CMMs from LK Metrology are ideal for high-speed tactile probe scanning and laser scanner applications of performance-critical components for automotive, aerospace and other applications.

Posted: February 26, 2019

For automotive, aerospace and other manufacturers needed faster inspection of performance-critical components, the Altera S multi-purpose compact CMM and Altera M high-speed production-type CMM with probe and laser scanning from LK Metrology, Inc. (Brighton, MI) can be fitted with Renishaw PH20 and REVO2 probes, CAMIO 8.5 multi-sensor CMM software, Renishaw Modus Software, and a Nikon L100 laser scanner. The Altera S has some of the most advanced capabilities in the compact CMM class. The machine is multi-sensor ready, allowing the user to expand the capability of the CMM as requirements change without the need for expensive controller upgrades. The Altera M delivers exceptional throughput and enhanced precision for production applications. Exclusively designed for high-speed tactile probe scanning and laser scanner applications, it is the preferred choice for automotive and aerospace and other manufacturers of performance-critical components.

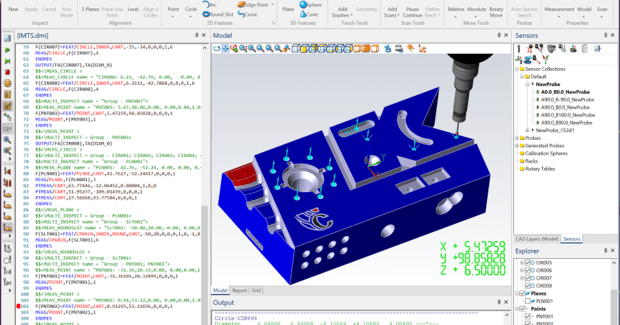

CAMIO 8.5 multi-sensor CMM software has a range of new features that accelerate lead times and improve product quality. Regardless of whether the user is inspecting stamped, molded or machined parts, CAMIO drives accurate and efficient inspection programs for geometric features along with full surface analysis with Part-to-CAD comparisons. Its interoperability across CMM platforms, sensor technology and manufacturing sites becomes its unique advantage. The software includes the following features/enhancements:

- Programming updates.

- Reorganizing of RPS alignments.

- Improvements in angle between tolerances to toggle between acute, obtuse supplementary angles easily.

- More precise and pronounced warning messages for users when setting machine/program parameters outside of min/max limits.

- The GOTO command now allows the user to specify the number of axes for move.

- Updated ACIS CAD engine and support for third-party CAD format.

https://youtu.be/kvVejINqvWY

User interface improvements include significantly better Window docking, CAD layers are displayed in a separate window for easier access, CAD orientation buttons allow the user to keep the current zoom level, and mouse/pointer coordinates shown in the status bar allow for quick estimation of dimensions. Laser and point cloud improvements include a new detection offset parameter for point detection and export of point clouds in a Geomagic® GDP format. There are also improvements in the setup of the Machine Launch Utility for offline programming, additional options for opening and/or printing CAMIO reports, and the ability to relocate a single stall of rack, instead of all the stalls. The Renishaw PHS1 servo head and autochange rack are now supported, and the Renishaw SP80 head and autochange rack are now supported.

LK Metrology, Inc., 12701 Grand River Road, Brighton, MI 48116, 810-263-6100, www.lkmetrology.com.