Easy and Intuitive Error-Free Robotic Programming

Robotmaster V7 software from Hypertherm makes the task-based programming of automatic integrated welding, contour trimming, cutting, dispensing, deburring, drilling and fastening easy and intuitive, even for first-time robot users with no expertise.

Posted: February 2, 2019

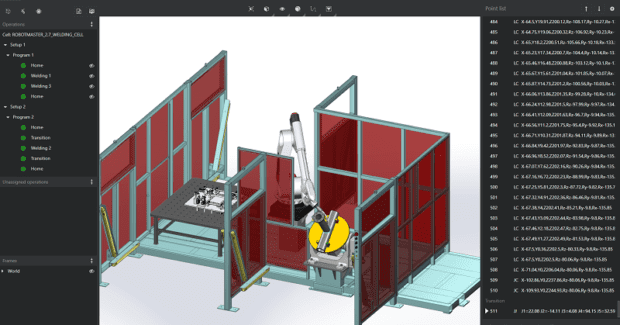

Robotmaster V7 software from Hypertherm Inc. (Hanover, NH) is a revolutionary task-based robotic programming platform that is based on a completely new architecture that makes programming easy and intuitive, even for first-time robot users. To create this new architecture, the Robotic Software group that developed Robotmaster added mathematical optimization experts who understand artificial intelligence and deep machine learning, as well as simulation and game experts who are passionate about user interaction. “Robotics and CAD/CAM expertise are not a prerequisite to create error-free robot programs with Robotmaster V7 because it is a task-based robot programming platform built around the user, for the user,” explained Chahe Bakmazjian, the head of strategy for the Robotic Software team at Hypertherm. “This software also has unmatched flexibility and configurability, and transfers the job to another robot brand or workcell without task reprogramming – an industry first.”

The new Robotmaster V7 software release targets automatic integrated welding and contour programming including trimming, cutting, dispensing and deburring, as well as drilling and fastening. It navigates complex part geometries and optimizes robot paths while synchronizing movements and preventing collisions between one or more robots, parts and tooling. It works for offline robotic programming in a variety of industries including aerospace, automotive, consumer electronics, power generation/energy and welding. Subsequent modules will enable additional tasks, including surfacing, 3D milling, additive manufacturing and inspection.

Hypertherm Inc., PO Box 5010, Hanover, NH 03755-3124, 514-225-2214, [email protected], www.hypertherm.com.