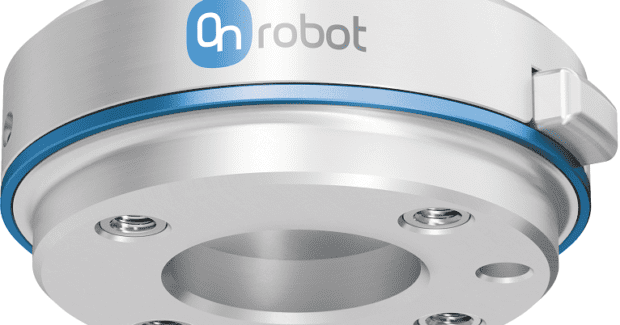

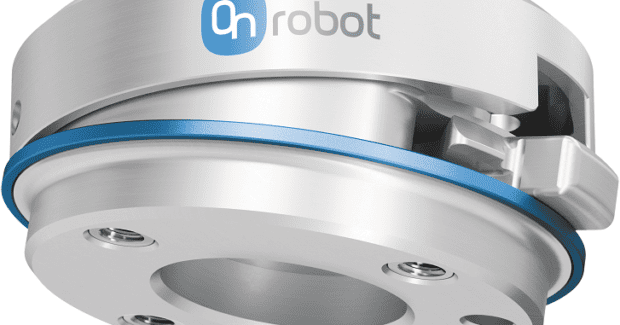

Change End-Of-Arm Tooling on Cobots in Seconds

With the lightweight Quick Changer from OnRobot, any operator can change the end-of-arm tooling on collaborative robots in a few seconds with just a click.

Posted: February 2, 2019

Weighing only 200 g (7 oz), the Quick Changer is a unique patented tool changer for collaborative applications from OnRobot Americas (Irving, TX) that has a low impact on robot payload. Its compact size adds minimal distance from the tool center point (TCP) to the robot, which minimizes stress on robot joints. The Quick Changer releases end-of-arm tools with just a click and inserted tools are automatically positioned correctly with a repeatability of ±0.02 mm. It can be used on any robot arm, drone, or other equipment with an ISO-9409-1 flange. “You no longer need to use heavy and clumsy tool changers with spiky handles and sharp plates sticking out,” noted Lasse Kieffer, the former chief executive officer of Purple Robotics (the Danish firm that developed the tool changer prior to being acquired by OnRobot) and now part of research and development at OnRobot. “This enables humans and cobots to work closely together in a safe and reliable manner.”

This tool changer is carried by a wide network of global distributors. “The height and weight of this tool changer are the lowest I have ever seen,” said Henrik Christensen, a product manager with OnRobot distributor Bila Robotics A/S (Nykøbing Mors, Denmark). “No matter what kind of tooling is installed on the robot, this quick changer is not in the way. It should be sold with all robots.” Along with easy and fast changing of tools, the patented technology in the Quick Changer is fully collaborative, with no sharp edges. It can handle up to 10 kg (22 lb) payloads with high repeatability. It has the lowest weight in class and lowest height in class and is ISO 9409-1, type 50-4-M6 compatible, with a redundant locking mechanism. “It lets us push one button to change the end effectors on our robots,” added Silas Robertson, the vice president of sales and marketing with U.S. distributor Olympus Controls (Tualatin, OR), who stressed the importance of improved changeover time. “This means never having to find a missing wrench to install the next robot end effector.”

OnRobot Americas, 222 West Las Colinas Boulevard, Suite 854E, #120, Irving, TX 75039, 469-442-9370, [email protected], onrobot.com.