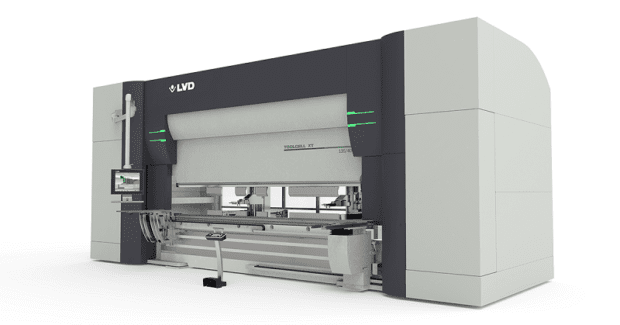

Automatic Tool Changing Press Brake with Extended Tooling Capacity

To efficiently bend small batch, high-mix parts, including complex layouts, with high accuracy in minimal changeover time, the versatile ToolCell XT automatic tool changing press brake from LVD Strippit holds 50 percent more tooling to handle varying material types, organize tooling by material type, and easily switch between stainless steel and mild steel applications.

Posted: February 19, 2019

The ToolCell XT from LVD Strippit (Akron, NY) is the latest generation of their ToolCell automatic tool changing press brake, with extended capacity to hold 50 percent more tooling than the original design. ToolCell XT is the system to efficiently bend small batch, high-mix parts with high accuracy and with minimal changeover time. The large capacity of tools housed within the press brake provides the flexibility to handle a wider range of bending jobs, including complex layouts. The system features an extended integrated storage of tooling and holds an impressive total length of tools: a maximum of 17,280 mm (±17.2 m) punches and a maximum of 40,320 mm (±40.32 m) dies. Extra toolboxes are integrated on both sides of the machine. ToolCell XT performs tool changes quickly and precisely, following an optimized tool change path. Automated tooling setup improves the efficiency of bending operations and eliminates time-consuming manual tooling adjustments.

With its extended tooling capacity, this press brake offers the versatility to handle varying material types, organize tooling by material type, and easily switch between stainless steel and mild steel applications. In small batch production, it’s critical to avoid costly test bends. ToolCell XT is equipped with the Easy-Form® Laser (EFL) in-process adaptive bending technology for real-time angle correction. EFL guarantees the desired angle from the first bending operation. The system consists of two laser cameras linked with an intelligent bending database in the Touch-B control. As the bending sequence of the press brake is initiated, the measuring device transmits the digital information in real time to the CNC control, which processes it and subsequently adjusts the depth to obtain the correct angle. The bending process is not interrupted and no production time is lost.

ToolCell XT also features the latest Touch-B control. Intuitive graphical icons are used to quickly and easily manage all parameters of the machine. The control is linked to a central CADMAN® database where all production-relevant data is stored. After importing a 3D CAD part, CADMAN-B (bending) software automatically calculates bend allowances and determines the optimal bend sequence, gauge positions and tool setups. This expertise is based upon expert algorithms for unfolding and collision computation during the complete bending process. ToolCell XT is offered in a 135 ton/4 m configuration, with other sizes to follow.

LVD Strippit, 12975 Clarence Center Road, Akron, NY 14001-1371, 716-542-4511, [email protected], www.lvdgroup.com.