Aluminum Grinding Reimagined

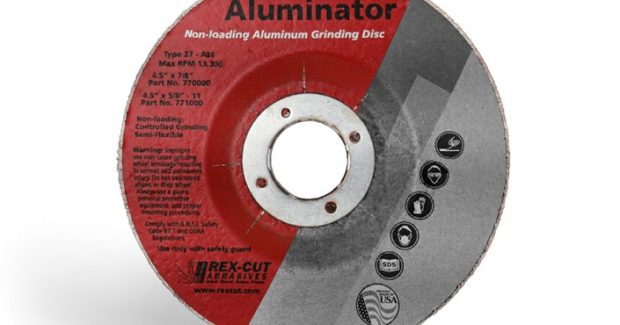

The Aluminator T27 cotton fiber grinding wheel from Rex-Cut Abrasives grinds aluminum fast and consistently without clogging and loading so that fabricators can grind and move on to the next step without stopping to clean the workpiece.

Posted: February 22, 2019

Typically, when grinding aluminum, bonded wheels overheat the metal and cause chips of aluminum to embed right into the grinding wheel. This is commonly referred to as clogging or loading. Eventually there is no grit exposed, only deposits of aluminum on the face of the wheel. Normally a wax or grinding aid is necessary to prevent this issue, but that is no longer the case. The Aluminator T27 cotton fiber grinding wheel from Rex-Cut Abrasives (Fall River, MA) grinds aluminum without any clogging or loading. Cotton fiber wheels naturally break down as heat is generated, resulting in constant sharp grit being exposed to the aluminum workpiece. This eliminates loading, costly downtime, and the need and expense for wax or grinding aids. The Aluminator T27 offers increased grinding action, greatly improved surface finishing, smooth operator control and long life. With less noise, less vibration, and safer operating conditions, the Aluminator T27 is assured to make every grinding experience smooth.

“One complaint we hear from fabricators working with aluminum is the need to take extra time to thoroughly clean lubricant residue from work surfaces after grinding. This happens from either grinding aids added to structure of the abrasive product, or waxes used in conjunction with grinding wheels,” explained Jon Blake, the R&D manager at Rex-Cut Abrasives. “When we designed this wheel, we kept in mind the need for an aluminum grinding wheel that will grind fast and consistently, while being 100 percent lubricant free. This allows fabricators to grind and move on to the next step without stopping to clean their workpiece.” The Aluminator T27 is now available in 4.5 in, 5 in, and 7 in diameters, in 36 grit.

Rex-Cut Abrasives also offers their Advantage premium Type 29 disc for faster and safer grinding using ceramic grinding power. Advantage is 100 percent more aggressive than a standard aluminum oxide grinding wheel and 70 percent lighter than a conventional grinding wheel. “The ultra-lightweight construction reduces vibration and operator fatigue,” stated Bob Costa, the president of Rex-Cut Abrasives. The state-of-the-art ceramic grain, combined with a proprietary backing, creates a disc with the toughness of a grinding wheel and the rapid material removal of a resin fiber disc. The ergonomic-modified Type 29 shape provides greater disc contact on the work surface to improve metal removal speed. Advantage is contaminant-free Fe + S + Cl < 0.1 percent and is engineered for stainless steel and carbon steel. This disc excels in weld bead removal, surface grinding, deburring, chamfering, and beveling. It is available in both 4½ in and 5 in discs sizes, in 36 grit for fast stock removal and 50 grit for a more refined surface finish.

Rex-Cut Abrasives also offers the Quick Change Disc Max, for deburring, blending, and finishing applications on all metals. These versatile quick change discs aggressively grind and blend while leaving superior finishes in one action using abrasive grain that is impregnated throughout the whole disc in layers of non-woven cotton. Non-woven cotton abrasives such as the Quick Change Disc Max feature a consistent finish throughout the life of the disc, so there is no need to dispose of discs that have not seen a full service life. “These discs achieve a 40 percent improvement in material removal rates and leave the same great finish as our original quick change discs,” added Costa. The Quick Change Disc Max lasts 4X to 5X longer than non-woven surface conditioning, as well as fiber or paper-backed coated abrasive quick change discs. It also removes metal more aggressively compared to unitized and leaves a more consistent finish compared to coated abrasives. The Quick Change Disc Max is available in 2 in and 3 in diameter sizes and 24, 36, 54, 80, and 120 grit, in either medium or flexible bonds. Samples and pricing are available upon request.

Rex-Cut Abrasives, 960 Airport Road, Fall River, MA 02720, 800-225-8182, Fax: 800-638-8501, www.rexcut.com.